Project conducted by the FactoryLab, industrial consortium, led by CETIM with support from R&D Vision and in collaboration with Naval Group, Stellantis, SLB and Safran.

Early detection of through and underlying welding defects to avoid reworking (post-process) and its significant cost and quality implications

In a stringent regulatory context, professionals who apply welding processes need to improve the performance and productivity of testing in order to stay ahead in a fiercely competitive market. Against that background, finding innovative and efficient solutions that allow technological breakthroughs can create a game-changing shift.

Conventionally, weld quality is tested either during the welding process (between passes) via surface methods (penetrant testing, magnetic particle testing), or after welding using surface and volume methods (X-rays, ultrasound). Such testing results in cumbersome repairs in the event of nonconformity.

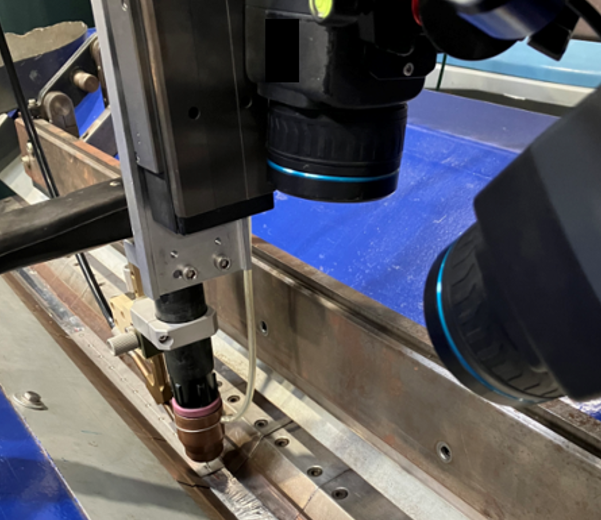

Non-destructive testing of welds during the welding process (online monitoring) could reduce or even do away with conventional tests by detecting the appearance of defects early on, and thus save time at the repair stage or the development of new welding processes. The Safran case of application, which was addressed as part of the QUALISOUD project, was the TIG welding process on 1mm thick butt-welded Inconel specimens with straight edges.

Identifying a configuration that is suitable for a good view of the welding scene

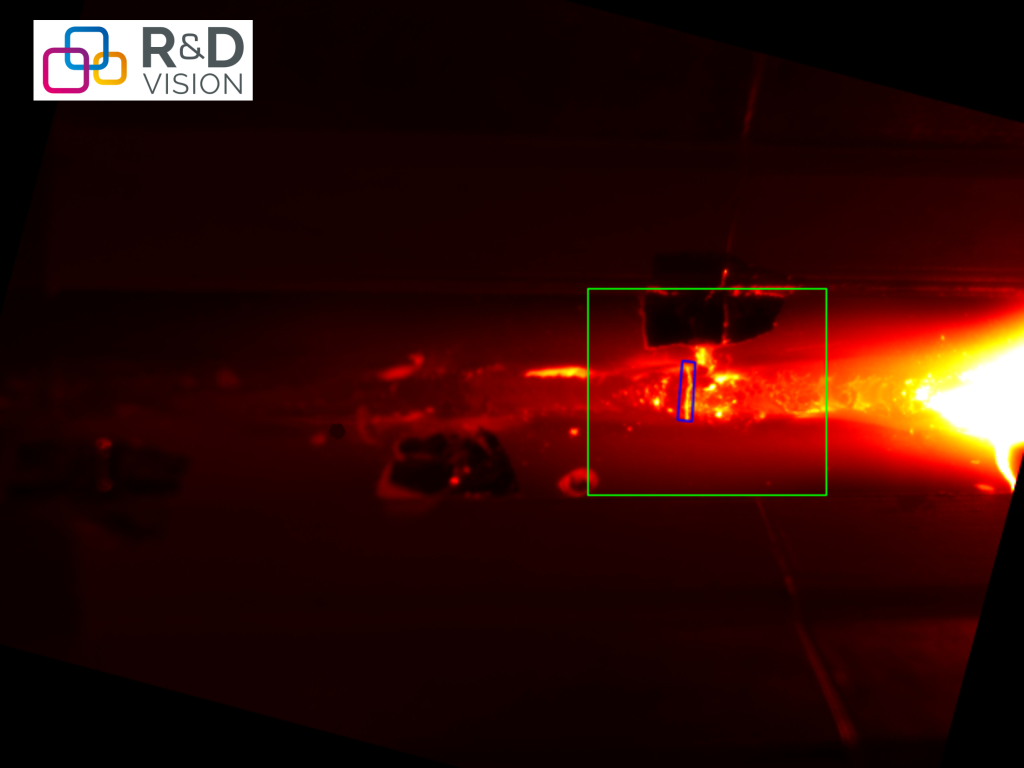

The first need in such studies is to obtain a clear view of the weld pool and/or bead as it cools (solidification and cooling area). Indeed, this stage is crucial for the rest of the study and, after a large number of tests with many adjustments, the saturation of the radiation emitted by the arc on the detector was successfully reduced, allowing a satisfactory view of the weld pool and the cooling bead.

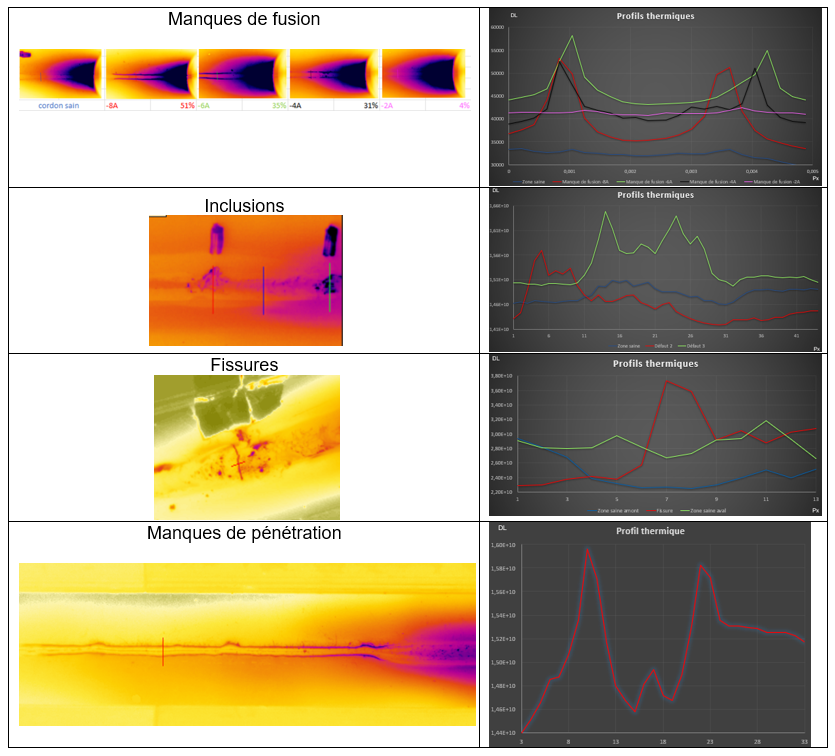

Creation and detection of the most common/harmful defects in such assemblies

After that, one must be able to create the required defects on demand; the defects that have been selected as the most representative (common/harmful) are incomplete fusion, inclusions, cracks and incomplete penetration. We were able to generate such faults by modifying the welding variables, and their detection was confirmed:

- Either solely by reading the thermogram during the acquisition and confirming detection using another non-destructive and/or destructive testing method;

- Or later on, after detection using another non-destructive and/or destructive testing method of an indication on the specimen and the confirmation of its presence on the thermogram and/or detection with raw data.

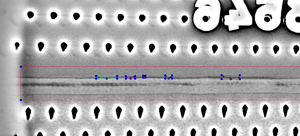

Repeatability of defect detection

In order to test the new technology, a phase relating to the repeatability of the detection of the four identified defects was applied. Incomplete fusion, inclusions and cracks could be reproduced several times and their rate of detection by infrared thermography was over 90%. Regarding incomplete penetration, first of all, it is rare in such joints, and its creation is not easy since it also produces incomplete fusion at the same time; lastly, as the weld is a butt weld, the back is open to the air and so there is very little radiative flux stored in the lack of penetration with little possibility of detection.

Photo credits: Cetim

It could be observed that in most of the tests carried out, a defect results in the following as a minimum:

- A radiative flux gradient;

- A heat signature;

- And/or a spatial shift.

The density trends of radiative flux due to the defects and their respective raw data suggest the possibility of automatic detection.

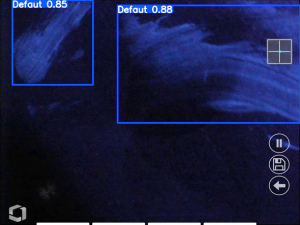

Automatic detection and processing of defects

R&D Vision thus worked on the possibility of automatically detecting some defects in the images obtained from thermograms. The goal stated by manufacturers is the ability to monitor the welding process in real time and to report or even locate the presence of anomalies in the bead. Two types of anomaly were processed as a priority, namely incomplete fusion and cracks. The visual signatures were significant, reproduced successfully during the experimental phases, and correlated by NDT reference methods.

Depending on the location in the image, the level of intensity was highly variable. Indeed, TIG welding generates a significant saturation effect at the weld pool (near the torch). A first processing stage was to study and carefully select the image zone with the best dynamics to be used. Several filtering methods were then tested and validated to suppress variable background noise.

Based on several video recordings, R&D Vision has developed an automatic detection method based on adaptive filtering to allow the extraction and finding of the signature of each defect. That algorithmic prototype is a first stage, which opens perspectives for the ability to detect defects in welding processes thanks to infrared thermography.

Photo credit: R&D Vision

Instrumentation of infrared thermography in industrial environments

The incorporation of thermography equipment by CETIM into production by SLB has shown the robustness of the instrumentation of the laboratory cameras in our possession in industrial conditions.

Conclusion and outlook

All the project phases were completed, including the viewing of welding scenes, the creation and detection of the discontinuities sought, the repeatability of detection and the possibilities of automatic detection and instrumentation.

Throughout the project, areas for technical, hardware and software improvements were detected, namely the sizing of indications (smallest detectable defect), the choice of a compact camera, software for acquisition, analysis and decision making, the correlation of welding parameters and the possible questions of hot repairs.

Author: Sébastien SAINT YVES, QUALISOUD Project Manager, CETIM and Laetitia LAVANCIER, Key Accounts Manager, R&D Vision.