Discover our innovation projects

Predictive maintenance, cybersecurity of connected objects, assistance in carrying loads, artificial intelligence, augmented control, monitoring and supervision… We innovate in each and every project.

- All

- Sustainable factory

- Physical assistance to operators

- Advanced controls

- Digital factory

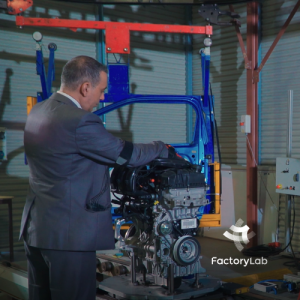

MANIPRES

The project resulted in significant productivity gains for the end users: assembly with submillimeter accuracy of the AGB in 30 minutes by an operator. Finally, it improved the quality of assembly by a better control of the effort of setting up and the absence of collision with the engine’s tubings.