Industrial innovation

at the centre of our expertise

From predictive maintenance to mixed reality, encompassing IoT instrumentation, optimisation of scheduling with constraints or real-time monitoring and simulation of key factors relating to the safety of personnel, industrial performance, adaptation of speeds and tools; see the technology implemented in our projects here.

One organisation for all

FactoryLab members define the areas of interest for the consortium and identify the projects to be initiated.

The projects cover all the technologies of factories of the future, see if they are relevant and applicable in a manufacturing context and derisk the development of functional solutions. FactoryLab qualifies and rationalises solutions to make them suitable for the reality of manufacturing shops.

Inventing more virtuous production modes

# Energy efficiency

# Carbon footprint

# Circular economy

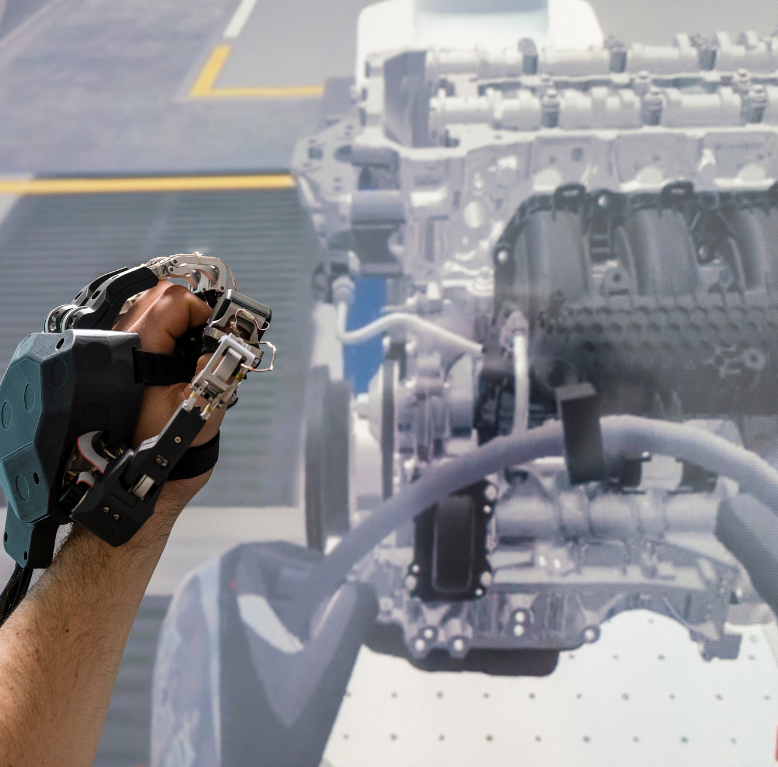

Creating innovative service or assistance tools

# Collaborative robotics

# Exoskeletons

# Semiautomatic guidance

Injecting digital intelligence into production processes and sites to increase efficiency

# Supervision and adaptability management

# Cognitive assistance to operators

# Operational efficiency

# AR/VR, wearable interfaces, human factors

Anticipating risks and optimising production quality through automation and continuous monitoring

# Control of parts and processes

# Automation and digitisation of production flow controls

Value creation lever for each partner company

FactoryLab offers a framework and brings its members together in favour of solutions that address common manufacturing constraints: sharing, innovating and testing, in order to bring a product or service to market. Each member contributes depending on its financing capacity.