PREHDIGIT: Demonstration of multi-finger robotic gripping

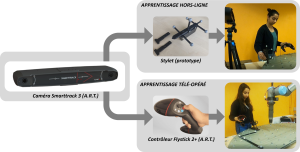

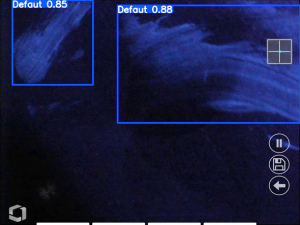

The PREHDIGIT project aims to demonstrate the contribution of multi-finger modular grippers that can adapt to different loads and shapes, to automate and allow the use of cobots in some industrial manipulation and handling tasks. By combining advanced mechatronics and teaching strategies, these systems aim to optimise productivity, heighten safety and improve quality, while making operators’ work less strenuous. The project focuses on the validation of their modularity and compliance with current manufacturing requirements.