PRECINET: Internal cleanliness inspection of piping

The PRECINET feasibility study is aimed at testing the approach of using artificial intelligence to detect pollution (grease and loose parts) in industrial piping, along with the possibility of incorporating AI into a video endoscope available in the market.

ERGOHAND: Interaction measurement glove

The project involved the creation of a tool that can measure the interaction between a human hand and the environment.

It led to the development of the multiphysics instrumentation of a glove and tests in operating conditions.

RACOSOUD: Determining the quality indicators of a welded joint based on the physical values recorded during welding

As part of the RACOSOUD project, high-performance tools for data processing, including those incorporating AI-based models, have been used in order to use the physical measurements collected during the welding process. The study was devoted to the resistance welding process.

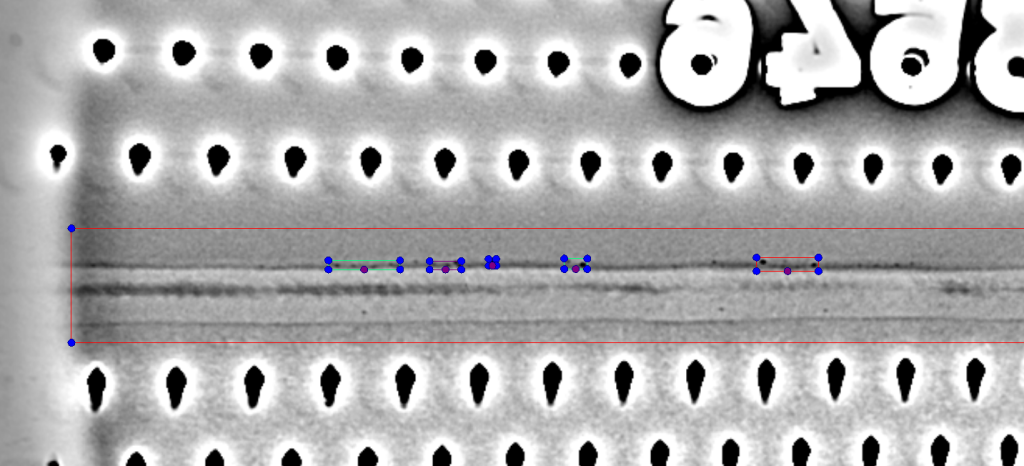

AUTO RX: Automatic detection of indications on X-ray images

The AUTO RX feasibility study is aimed at testing several approaches for putting in place a system that uses artificial intelligence to assist decisions based on digital X-ray images. The study compares two techniques adapted to limited image bases with a standard approach.

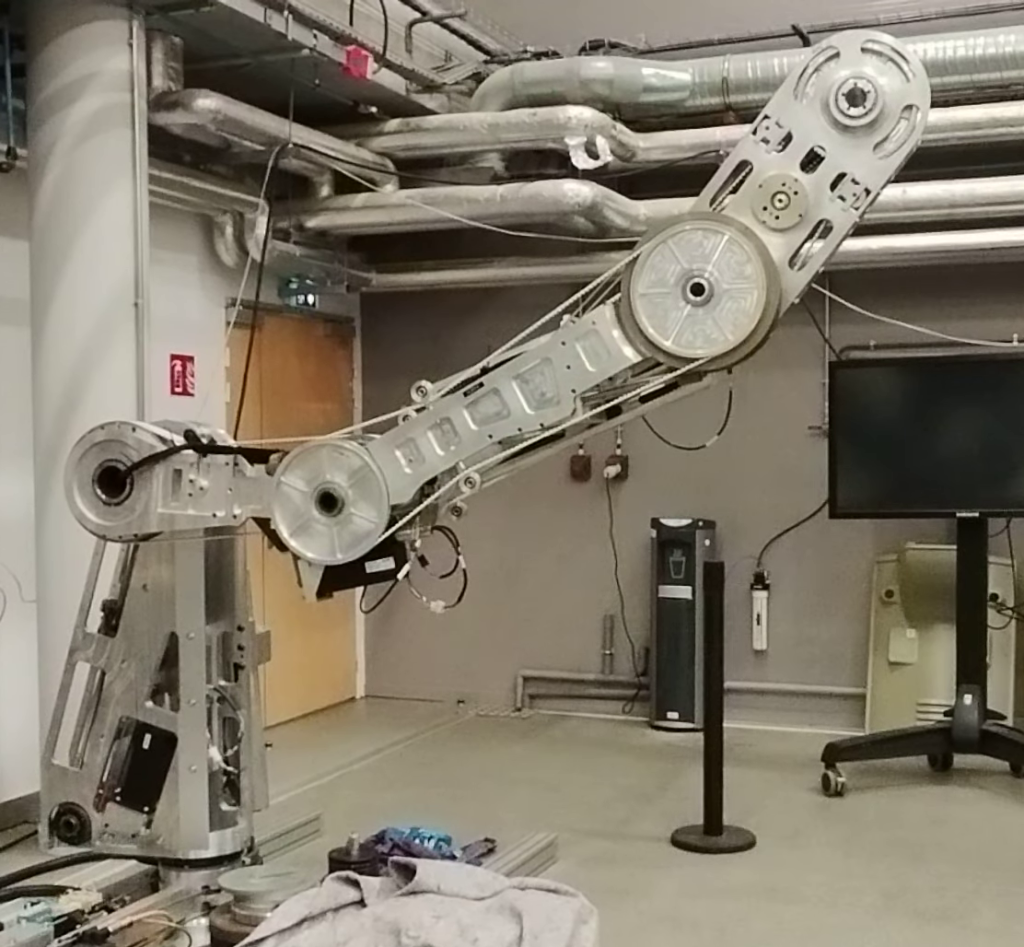

ASSISROB: SybXL, design, innovation and challenge of a heavy payload cobot

Designed to address the need for a collaborative robot that can handle heavier loads than those available in the market, SybXL is an innovative heavy payload (35 kg) cobot that is the result of collaboration between CEA-List and industry. While not all the challenges relating to the design of such a cobot have been met to date, major scientific advances have been made, such as a double-acting cable cylinder which synchronises the axes or a balancing system with multiple springs.

FactoryLab programme position review

Comparative study of the players of Industry 4.0.

TEKNUM: Multimodal digitisation techniques in manufacturing environments

The aim of the TEKNUM project is to develop in-depth and up-to-date understanding of 2D, 3D and multi-scale and multimodal digitisation technologies to detect faults in a manufacturing environment, with the best compromise between precision, speed and cost.

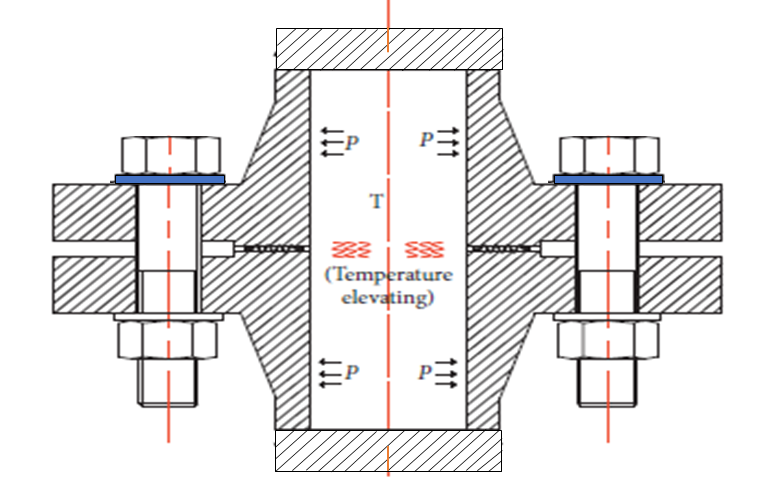

CESAME F: Shape Memory Alloys for Clamping and Sealing

The CESAME F project is aimed at studying functional needs to better control clamping and sealing thanks to shape memory alloys, which offer a potential advantage to industry.

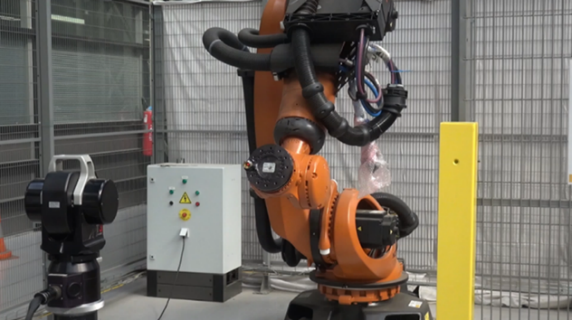

ROBOPRECI: Study of the precision of manufacturing robots

The ROBOPRECI feasibility study aims to test and propose a static and dynamic method for testing robots, to add to standard ISO 9283, which currently allows the assessment of the static performance of industrial robots, but is still too generic.

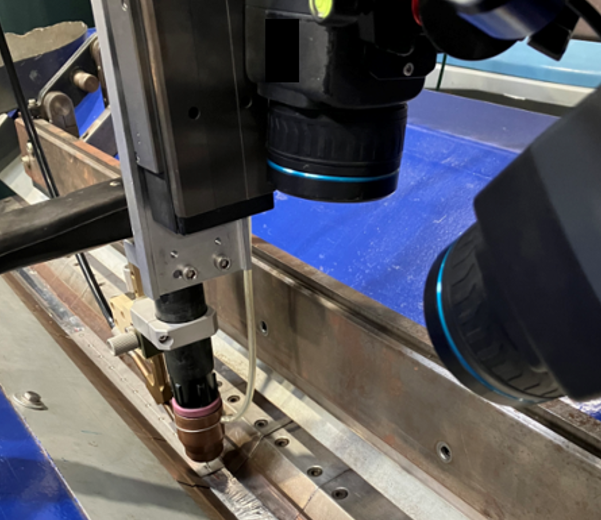

QUALISOUD: In-process welding quality using infrared thermography

The QUALISOUD project was aimed at determining the ability of passive infrared thermography to detect geometrical and material soundness defects in welds.