Project conducted by the FactoryLab industrial consortium with cross expertise from CEA-List, CETIM and ENSAM-Lille, in collaboration with Isybot, Dassault Systemes, Actemium, Safran, Naval Group, Stellantis, TechnipFMC, Vinci Construction and Bureau Veritas.

Background: cobotics, a human-centred approach

Cobotics, or collaborative robotics, focuses on collaboration between robots and humans. Unlike conventional robots that operate in isolation in separate environments, collaborative robots are designed to work hand in hand with operators, in the same workspace. Such close and safe interaction is aimed at improving the working conditions of operators by making tasks less strenuous and reducing the risks of occupational diseases, particularly musculoskeletal disorders (MSDs).

The aim is to relieve workers from repetitive, strenuous or hazardous tasks, while allowing them to focus on activities with greater added value. By taking charge of significant or repetitive physical efforts, cobots help prevent MSDs and improve working conditions. Further, cobotics can help improve the quality of work by reducing errors and increasing the precision and repeatability of operations.

Cobotics is used in a variety of areas such as manufacturing, logistics and healthcare, and is the missing link between automation and purely manual work. It promotes a more inclusive and synergistic approach, where people and machine collaborate to achieve optimum efficiency and safety. By placing emphasis on the complementarity between human workers and robots, cobots are used as tools that augment the abilities of operators, without replacing them.

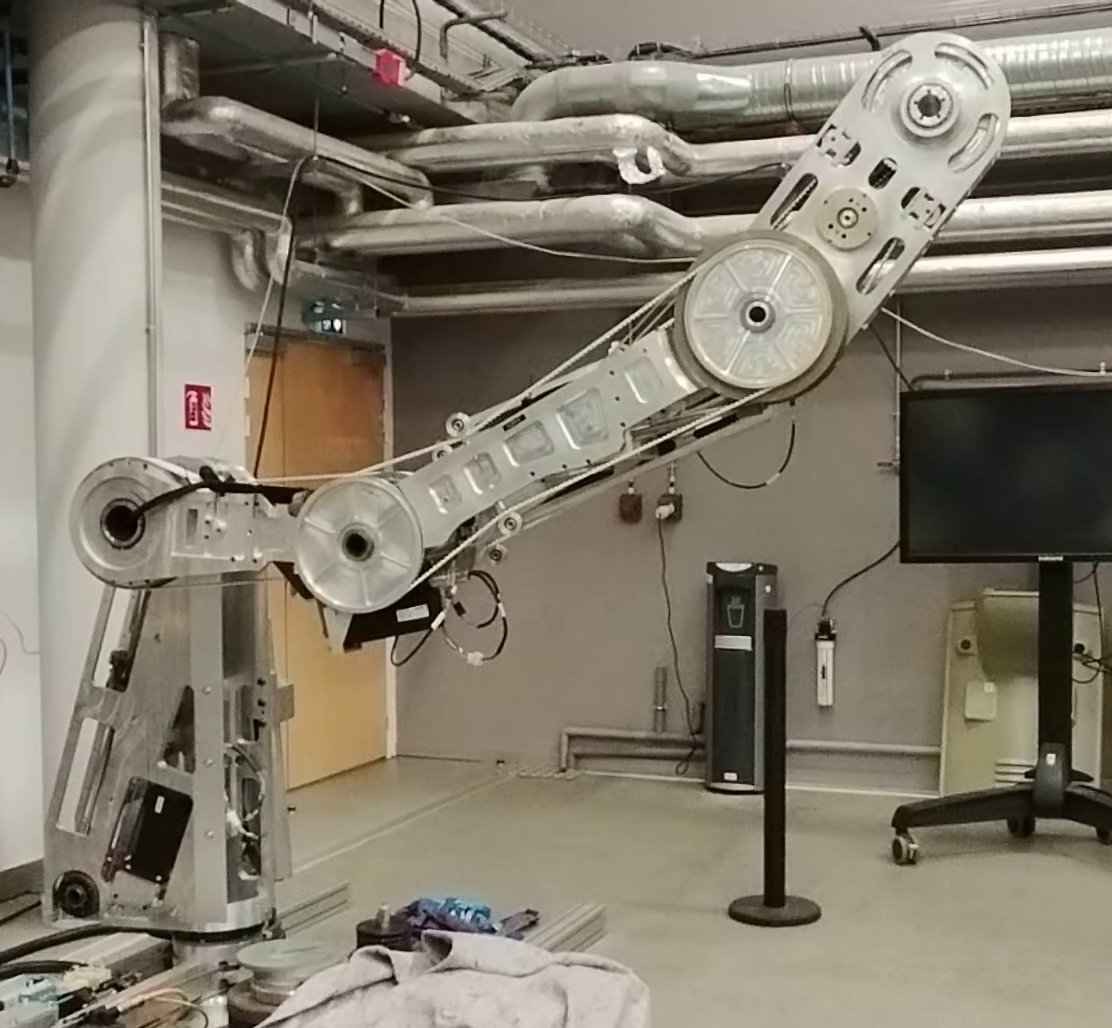

Concrete example: the Isybot cobot, fruit of the research by CEA-List, is a perfect illustration of this human-centred approach. Designed to enhance the competitiveness and appeal of manual jobs, it improves productivity while reducing operator fatigue, without modifying the environment. Thanks to its unique patented mechanical qualities, Isybot adds competitiveness and appeal to non-automated and unforeseeable tasks. Interactive cobots improve productivity while reducing operator fatigue. The current cobot, SYB 3, has a range of 1.6 m, a payload of 10 kg and four operating modes: assistance, restitution, concurrent work or remote control. Operators with no particular training can incorporate and optimise the use of the cobot and exploit their know-how.

Challenges

The aim of the ASSISROB project is to increase the payload of the Isybot collaborative robot to reach 35 kg. There are few cobots in the market offering such a payload. That load-bearing capacity ought to address a large number of use cases of FactoryLab end users.

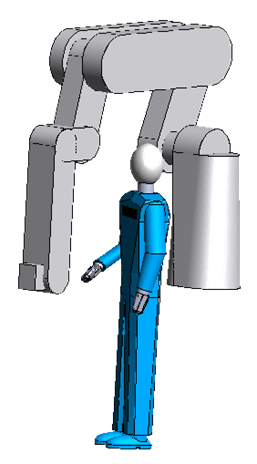

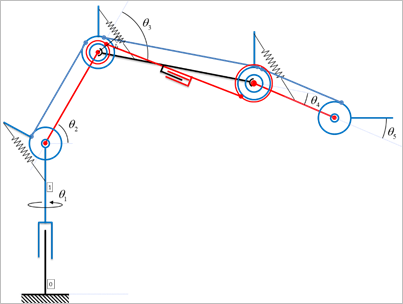

To meet the requirements of as many users as possible, the designers have developed a concept where axis 3 of the robot is made up of two coupled segments (see below).

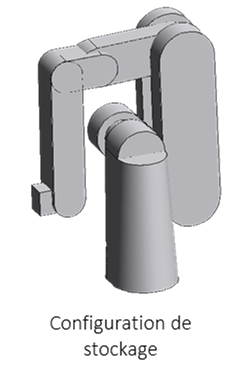

The aim was to limit the number of controlled axes to three, like with Syb 3, in order to minimise the cost and complexity of the circuitry, at the same time minimising the dimensions of the robot when folded. Those compact dimensions would enable the robot to go through standard workshop doors and into most lifts and work platforms, in order to allow greater mobility and the facility to work in very diverse situations. Once deployed, the robot has a 2 m range.

Innovation

The robot has been designed and made. It operates in robot mode and is compact when it is folded. A complete model of the robot, including friction, has been developed and validated. The main parameters have been identified. Thanks to that design, the robot can be folded back to fit on a pallet, and its folded height is low. In spite of those constraints, its working area is very large.

However, the robot is not easy to manipulate in cobot mode. It tends to go into a singular configuration (a robot reaches a singular configuration when it is loses all or part of its mobility. As a result, the robot may encounter difficulties to reach or leave that position smoothly), making the manipulation of some axes more difficult.

The SybXL stands apart by its innovative architecture, which gives it compactness and high performance. The double-acting cable cylinder plays a crucial role by kinematically coordinating axes 3 and 4, thus making it possible to control only three axes while retaining large amplitude of movement. This system, which includes a cable transmission to synchronise the two axes and a cable actuator to supply the required force, is the key element for reducing the size of the robot once folded.

To keep the arm balanced (see the kinematic model below), the SybXL uses the conventional solution of several serial belt parallelograms. Besides, a spring balancing system is put in place on three axes. That choice of design, which relies on series and parallel groupings, helps reduce the mass of the robot (springs are lighter than conventional counterweights). Spring manufacturing uncertainty is taken into account at the design stage.

Lastly, the use of high-capacity cylinders enables the SybXL to support an increased payload, thus addressing the needs of end users.

Results and outlook

The development of a high-powered collaborative robot with synchronised axes remains a complex scientific challenge. The SybXL designed as part of the ASSISROB project offers a high payload within a controlled size. That work has made it possible to approach a new area, which will help extend the capacities of cobots to offer greater autonomy and a real robot mode.

However, tests showed that transparency is insufficient in some configurations. The 3-4 axis has a tendency to spontaneously go into a singular configuration, which considerably reduces the manageability of that axis. The resulting ergonomics are therefore highly reduced.

All the same, this project has enabled major scientific advances:

- work on balancing has helped improve knowledge about the uncertainty of springs;

- the development of an actuator of the double-acting cable cylinder type makes it possible to elegantly synchronise 2 axes;

- lastly, a methodology to identify the machine parameters separately without disassembly has been developed and implemented.

Author: Frédéric COLLEDANI, ASSISROB Project Manager, CEA-List.