Project conducted by the FactoryLab industrial consortium, with expertise from two laboratories of the DIASI department of CEA-List (LISA and LVML), in collaboration with the manufacturers Stellantis, Naval Group and Safran.

Research question

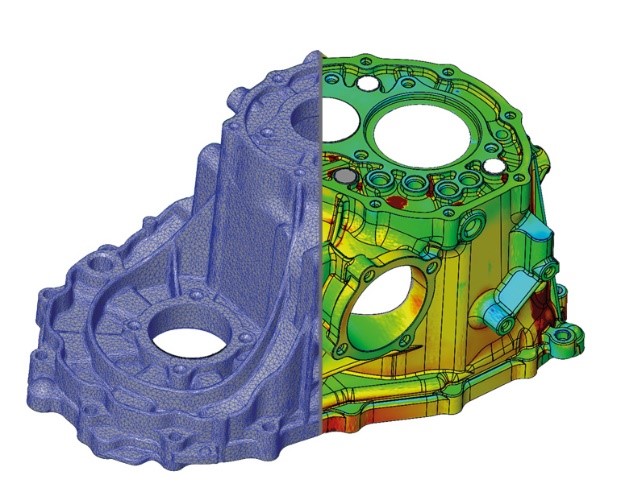

The digitisation of manufacturing spaces and equipment has become a major challenge in the current context of the digital transformation. With the rapid growth of digital twin technologies based on precise digital dimensions, many opportunities have opened up for significantly improving manufacturing. Digital twins are used to create true virtual replicas of manufacturing equipment and processes, thus facilitating management, optimisation and predictive maintenance.

In that context, end users are increasingly looking for more optimisation of the triptych made up of precision, speed and cost. The search for that balance is essential to make sure that digitisation solutions address the specific requirements of each manufacturing application. Digitisation needs vary considerably depending on the final application. For a mechanical part, fine details and strict tolerances are a must, for reasons relating to performance and safety. On the other hand, digitising a workspace may be chiefly aimed at making it more ergonomic or planning and managing space, where more flexible tolerances are often acceptable.

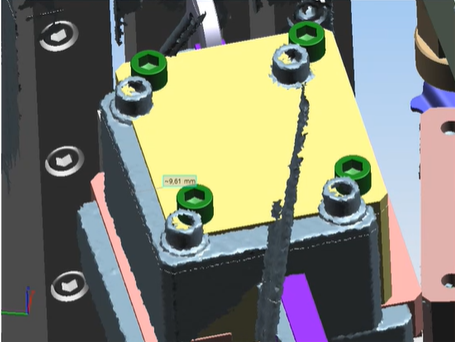

The detection of defects as part of digitisation processes is an issue that is often neglected in the literature. However, this is a key area of study for many industries, where product quality and reliability are crucial. Defects may be geometric (deviations in shape), dimensional (deviations from specifications) or structural (cracks, porosities). The ability to combine digitisation with defect detection opens new perspectives to ensure high quality levels and reduce the costs of nonconformity. Faced with the diversity of the solutions available in the market and the different needs for defect detection, selecting the most appropriate digitisation technology may be complex. Companies need to take account of several factors, such as the type of defect to detect, the precision required, time and budget constraints, and compatibility with existing systems. Solutions vary from high-resolution 3D scanning systems to more flexible handheld devices, each of which has its own advantages and limits. The digitisation of manufacturing spaces and equipment is a key component of the modernisation of manufacturing processes. By balancing precision, speed and cost, and by integrating the ability to detect defects, companies can not only improve the efficiency of their operations, but also guarantee superior product quality. The diversity of needs and available solutions makes this area dynamic and ever changing, offering new opportunities for innovation and industrial optimisation.

Goal

The goal of the TEKNUM project is to establish in-depth up-to-date understanding of 2D and 3D digitisation technology for manufacturing applications. First of all, the technical and commercial state of the art of different digitisation approaches must be established in order to identify existing solutions, their capacities and their limits. That stage will help create a complete panorama of the technology available in the market and its potential applications in a number of manufacturing contexts. Then, the project aims to precisely identify and document the specific needs in the area of digitisation. That will be combined with an assessment of the measurement ranges needed, the required precision levels and the types of technology that are most appropriate for the envisaged tasks. Besides, particular attention is paid to the types of defect to identify, whether these are geometric, dimensional or structural, in order to make sure that the selected digitisation solutions can effectively address those requirements. Lastly, TEKNUM seeks to look at the outlook and make recommendations for the choice of the most suitable digitisation technologies, based on concrete cases of use. That approach is aimed at guiding the choice of technologies towards those that offer the best compromise between precision, speed and cost, while addressing the specific needs of the targeted industrial applications.

Use-case

– Safran: structural inspection of infrastructures at a height;

– Naval Group: digitisation of the working area of a large gantry for the purpose of simulation;

– Stellantis: visual and structural inspection of complex assemblies.

Results

TEKNUM has brought out the hard and software solutions for 2D/3D digitisation, their positioning and their limits. Regarding the hardware architecture, the study has made it possible to precisely identify the criteria to apply while selecting a 3D scanner. These criteria include digitisation precision, capture speed, compatibility with different industrial materials and environments, and cost and ergonomics considerations. Those criteria were subsequently used to generate a decision tree that can help the user select hardware architecture that is adapted to their specific needs, thus facilitating a more informed and efficient choice of equipment.

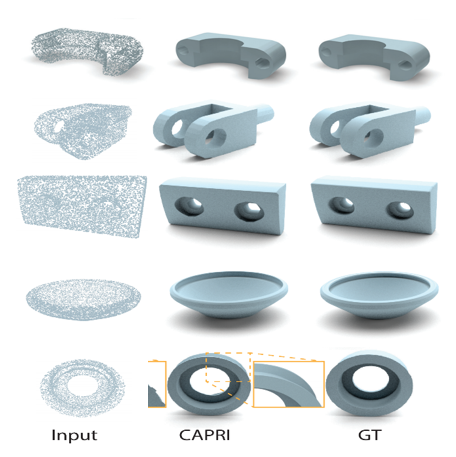

Regarding the part of the study that relates to software architecture, TEKNUM has brought out the various solutions of the state of the art for processing and using scatter chart data. The study explored data processing algorithms, 3D modelling software, and the tools for analysing and viewing the results. TEKNUM also assessed the capacity of software to include digitisation data in existing workflows, and its compatibility with other industrial management systems.

Lastly, the TEKNUM study offers suggestions and guidance for work to handle identified specific use cases, particularly that raised by Stellantis. Those recommendations include suggestions for improving digitisation processes, strategies for detecting and analysing defects, and proposals for the harmonious integration of digitisation technologies in existing industrial environments. The study thus opens the way to future developments and improved adoption of 2D/3D digitisation technologies in industry, by providing a clear and detailed roadmap for future stages.

Outlook

The exchanges that took place throughout the project, whether in the form of informal discussions, progress reviews or workshops, were essential for defining a promising subject that could be covered by an instruction during future batches of FactoryLab. The subject relates to the use of advanced software techniques for fault detection and reconstruction in complex assemblies. The interaction made it possible to identify the specific needs and technical challenges associated with such assemblies, and brought out the opportunities for improvement and innovation. The aim is to develop reconstruction algorithms that can generate precise and reliable 3D models from digitisation data, while integrating high-performance defect detection systems to identify geometric, dimensional and structural anomalies in assemblies. The project could be of great benefit to manufacturing industries, as it improves the quality and reliability of end products, while reducing defect-related product costs and optimising quality control processes.

Author: Mehdi BOUKALLEL, TEKNUM Project Manager, CEA-List