Project conducted by the FactoryLab industrial consortium with the cross expertise of CEA-List, CETIM and ENSAM in collaboration with SLB, Naval Group, Stellantis and Safran.

Background

The accuracy of industrial robots is an important characteristic for the choice of a model, depending on the process that will be implemented by its application. The specifications claimed by robot manufacturers often do not cover their path tracking accuracy or their accuracy under variable force.

In view of the difficulty while implementing robotic solutions through offline programming, particularly due to the lack of the path tracking accuracy of robots, it is relevant to define means and a method to assess the static and dynamic performance of robots, in no-load and operating conditions. And to assess the particularities of robot paths.

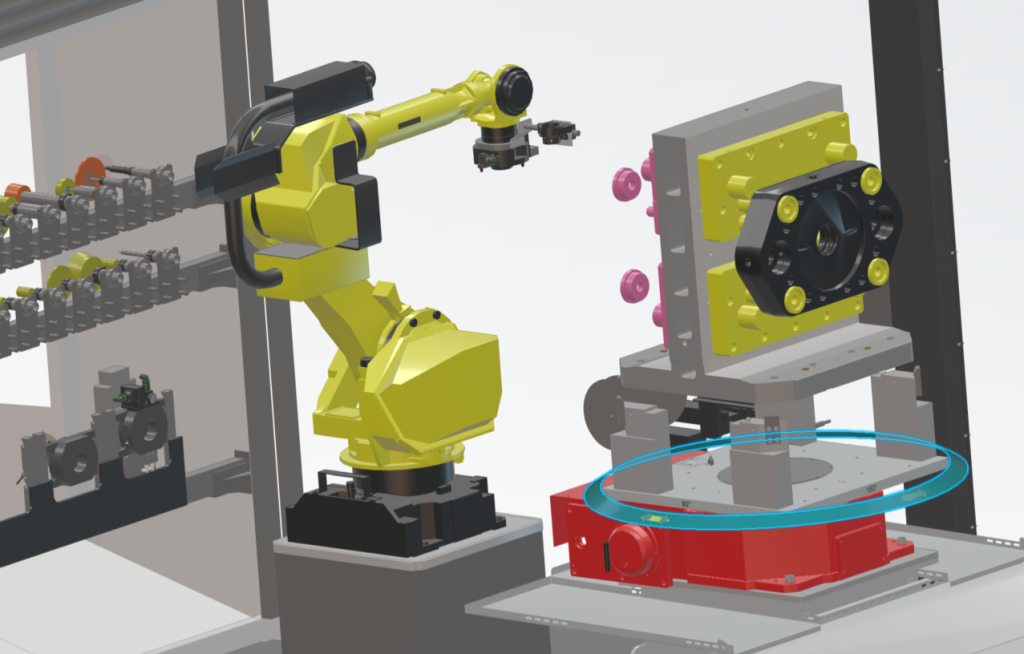

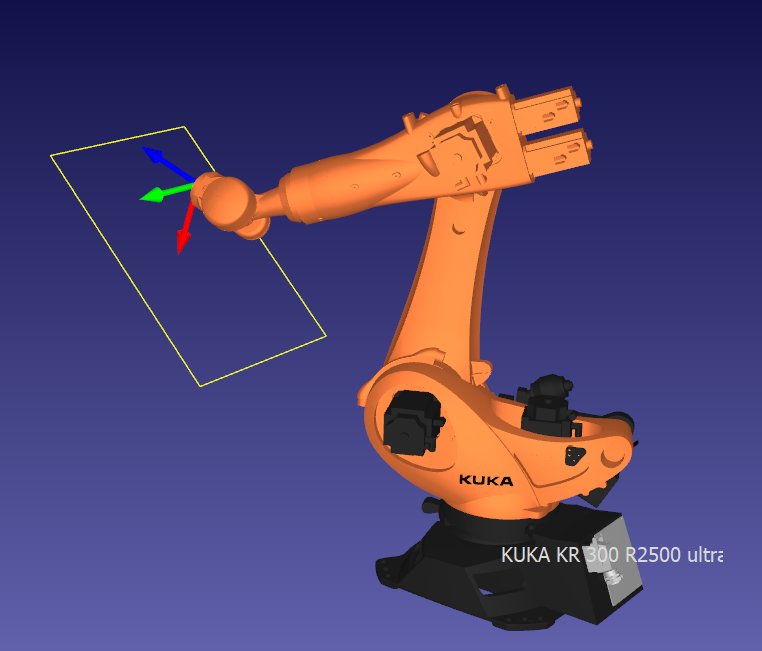

Our main study case was proposed by SLB (Figure 1): measuring path tracking accuracy during an operation for finishing a part, transposed on a Fanuc robot of ENSAM. The case was complemented by measurements made by CETIM (Figure 2).

Credits: SLB

Credits: CETIM

Challenges and innovations

The challenge was to obtain a standard methodology for assessing the dynamic repeatability and accuracy of a conventional poly-articulated robot in static and dynamic conditions, taking account of influential parameters such as path, speed, acceleration, payload or positions in the working space. The solutions assessed had to be robust, have reached TRL9 industrial maturity, and be available in the French market.

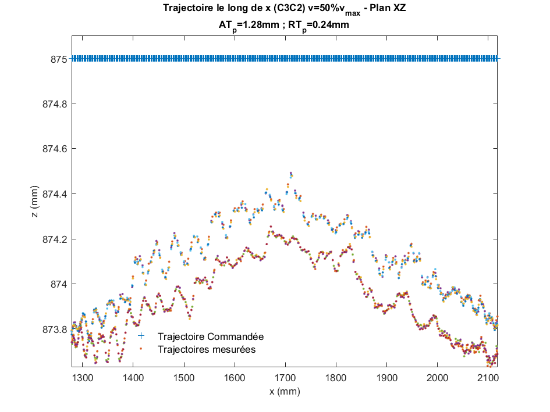

Standard ISO 9283, which assesses the performance criteria of industrial robots, remains very generic. It was thus analysed during the project and we were able to test a few additional protocols (Figure 3) that could be added to it. The impact of the choice of different robot path and pose references was studied in particular. Further, the study allowed the addition of a further assessment criterion: the hysteresis observed during the path measurements taken in 2 opposite directions (Figure 4). Lastly, for a better fit with industrial processes, the study approached the impact of path smoothing on the accuracy of the robots.

Credits: ENSAM

Credits: ENSAM

Results

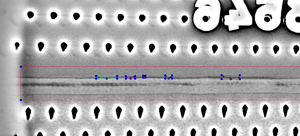

The feasibility of measuring the static and dynamic accuracy and repeatability of serial robots using laser tracker type measuring systems (Figure 3) and stereo vision (Figure 2) was demonstrated during the study. A rough methodology was used to put in place a simple generic protocol using these systems and obtain a first generic assessment (Figure 5). The methodology chiefly relies on standard ISO 9283 (Figure 6), slightly supplemented with the results of the study.

The campaign conducted in ENSAM using the Fanuc robot, measured by an API laser tracker (Figure 4) brought out, in addition to smoothing, the choice of the measurement reference system and the hysteresis phenomenon, and the influence of speed on measurements.

Besides, the measurements made by CETIM Sud-Ouest on an ABB robot using a Creaform stereo vision tracker or an AT950 laser tracker have allowed the establishment of correlation between the systems and brought out the viability of the alternative offered by stereo vision.

Credits: ENSAM

Credits: ENSAM

Outlook

The methodology proposed in this study is rough, and must be supplemented to become more generic. We still need to continue testing, more specifically, among others, considering the forces applied during the operations and with a deeper understanding of the effects of path smoothing.

Before production engineering, finding a solution that is adaptable to different hard and software, with an easily accessible interface, requires dedicated development and could be the subject of a project in its own right. We could envisage the inclusion of path correction.

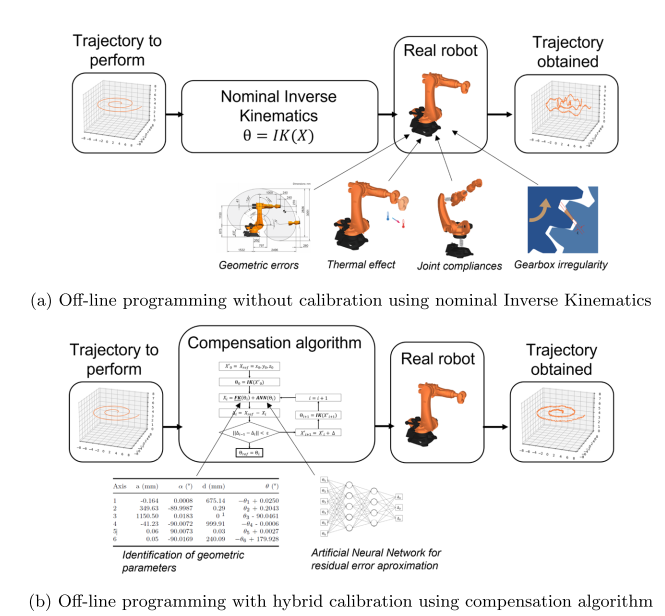

Note the existence of hybrid calibration projects that combine the identification of the geometric parameters of the robot with an artificial neural network to obtain an approximation of the residual error (Figure 7); allowing the improvement of the accuracy of the robots.

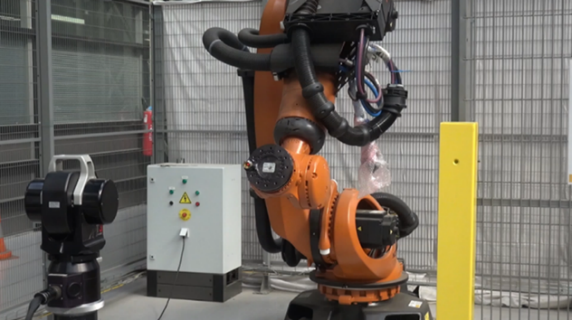

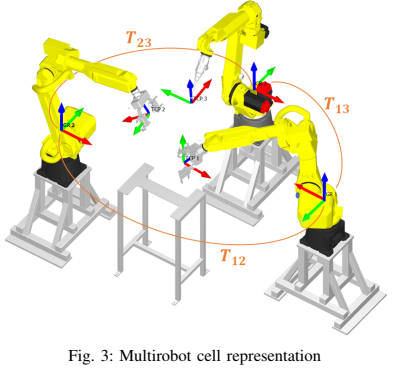

Lastly, projects for calibrating multi-robot cells are under way (Figure 8) and could be extended in order to complement and continue this study.

Credits: ENSAM

Credits: ENSAM

The feasibility of measuring the accuracy and repeatability of robots in static and dynamic conditions has been demonstrated through the ROBOPRECI study; a rough methodology to add to standard ISO 9283 was proposed and could be improved more specifically, possibly as part of new projects that extend the study.

Author: Grégoire DEBRAS, ROBOPRECI Project Manager, CETIM