Projet réalisé dans le cadre du Consortium industriel FactoryLab avec le CEA-List, le CETIM, FINRIP, STELLANTIS, SAFRAN, NAVAL GROUP et SLB.

Background

Industry does not currently have modular grippers with a variable load capacity. Until now, automation was essentially devoted to manufacturing in large runs, mainly for repetitive tasks. Parts were handled using specific grippers, which were designed for a single task.

Today, an operational transformation is under way in factories: production must be capable of adapting to a wide diversity of parts (in terms of shapes, geometry and weight), at the same time allowing quick reconfiguration, particularly for specialised production in small and medium series. That change is accompanied by heightened requirements in terms of speed, competitiveness, sustainability and quality.

- STELLANTIS: manipulation of reinforcements for roofs and doors, preparation of gear box kits etc.

- NAVAL GROUP: holding of tubes of varied sizes and shapes during welding operations, etc.

- SAFRAN: holding of engine parts in the production process, handling of engine subassemblies during testing, and assistance tools for after-market engine maintenance, gear maintenance etc.

- SLB: handling and turning over parts in steel, mechanical engineering workshops, varied shapes, heavy loads etc.

Challenges & innovation

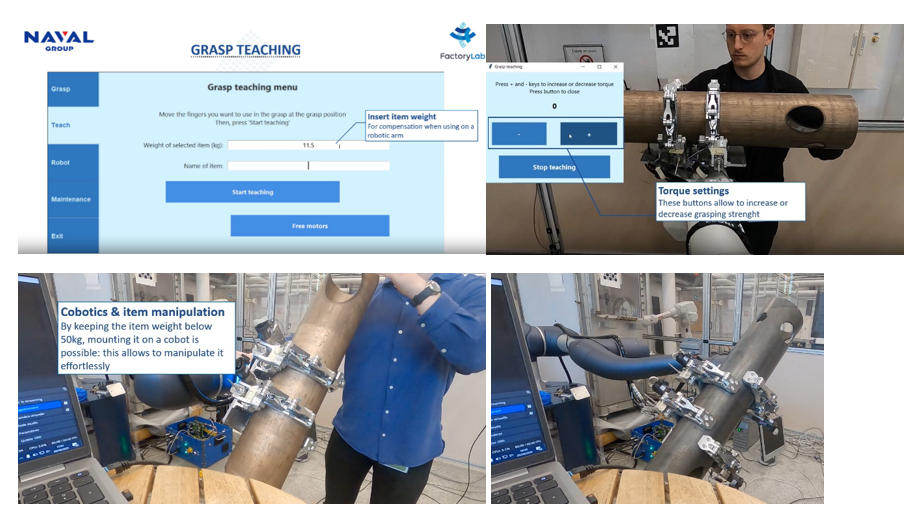

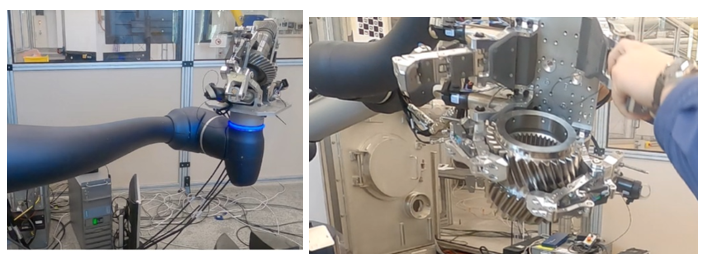

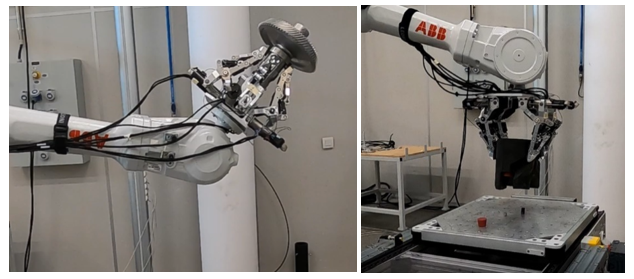

The main challenge was to demonstrate the value of multi-finger robotic gripping of the objects in the use cases identified in the study. To that end, FINRIP offered to develop a standard modular range of fingers and multi-finger grippers that can grasp a large variety of objects, from lightweight loads (< 1 kg) up to several tens of kilograms. The aim is to address the specific industrial gripping needs of robots and cobots, by adapting to a large number of contexts and a variety of industrial applications.

As part of the PREHDIGIT project, the grippers will incorporate prototypes of sub-actuated robotic fingers with three phalanges, based on the early mechanical architectures developed by CEA-LIST.

The aim is to validate the ability of this conceptual approach to fully address the expectations and requirements of end users in industry, particularly in terms of modularity, flexibility, ergonomics, safety, compliance with standards and ease of integration.

This innovation can thus automate and/or cobotise tasks by offering a system that can:

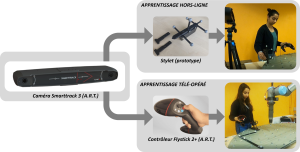

- effectively collaborate with operators, thanks to smart operating modes based on teaching.

- operate in fully automatic mode.

Eventually, the impact on industrial use ought to lead to a significant increase in operational performance (enhanced productivity, more precise assemblies, reassignment of operators to tasks with greater added value), greater safety of operations, improved quality, and a reduction in strenuousness by making handling effortless for the operator.

Results

A gripper prototype based on interchangeable palms with modular fingers from FINRIP was designed and integrated in a demonstrator installed in the premises of CEA-LIST. Successful demonstrations have validated the relevance of the mechatronics and command and control approaches selected for the design of the modular robotic fingers, and that of the gripper overall.

Besides, CETIM provided its expertise in the area of safety, helping to direct future developments in order to ensure the compliance of the next range of fingers from FINRIP to safety requirements, particularly in respect of perception, actuation, structure and the command and control component.

Prospects

The inclusion of safety requirements in the designing of the controls of the gripper is one of the short-term prospects of this work.

Conclusion

The robotic gripper prototypes developed as part of the PREHDIGIT project fully addressed the requirements of the representative use cases supplied by the end user partners. This project was a crucial stage for FINRIP, as it allowed a better understanding of market needs, while moving their product towards a higher technology readiness level.

Author: Mathieu GROSSARD, PREHDIGIT Project Manager, CEA-List.