Project conducted by the FactoryLab industrial consortium. The partners who collaborated with the project were: the technology provider RACER, a French glove maker, end users Stellantis, Safran and Naval Group,and several laboratories of CEA-List/DIASI.

Background

This project follows a previous FactoryLab project named ERGOFORCE. That first project led to the development of software to calculate the postures and efforts induced by the working environment on the body of a manufacturing operator as they carry out their tasks.

To carry out the calculation, sensors were placed on the operator. But hand measurements were not possible, because no instrumented tools were available in the market.

The ERGOHAND project is aimed at filling that gap and creating a measuring tool that is suited to the hands of the operator.

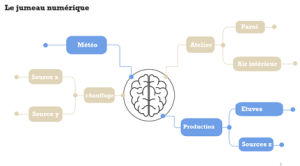

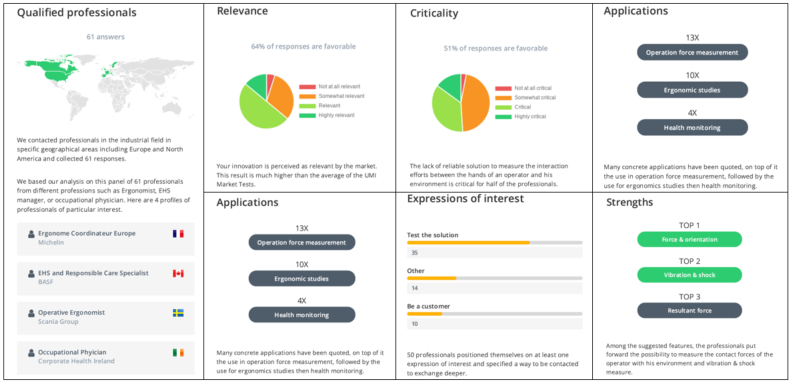

In the course of the project, other sectors exhibited an interest for the solution. That need was brought to light in a market survey carried out by UMI. As presented in the charts below:

Challenge & innovation

The challenge thrown down by the project was the faithful acquisition of the force applied by the operator’s hands on the environment. And also the ability to capture the vibrations and postures imposed on the operator’s hands by the environment.

Merging data between the measured efforts and postures enabled us to reconstruct an effort oriented in space.

Such acquisition must be possible without coming in the way of the movements gestures of the operator.

The measurement tool takes the form of a pair of connected gloves fitted with sensors:

The sensors on the glove are as follows:

- On the inside of the hand

- 12 pressure sensors are distributed over the palm and fingers. These sensors measure the effort of interaction between the hand and the environment.

- On the back of the hand

- 10 flexion sensors measure the two degrees of angulation of the joints between the metacarpal bones, the proximal phalanges and the intermediate phalanges. The angulation of the joints of the distal phalanges is considered to be coupled with the previous ones.

- Five inertial measurement units (IMUs) are placed on the intermediate phalanges in order to provide a second source of information about the angulation of the articulations (that source of additional information is particularly important on the thumb because of its multidimensional movements with significant amplitudes).

- On the wrist

- One IMU is placed above the wrist (wrist angulation is calculated as the difference between the two IMUs of the hand and wrist)

Calculation and communication unit

A microprocessor collects all the information and sends it on via Bluetooth to a computer every 7 ms.

Results

Several iterations of the glove were made during the project to develop a demonstrator, which was then assessed in operating conditions in manufacturers’ facilities.

The gloves were assessed for the following operations at Safran and Stellantis:

- Torque tightening

- Screwing

- Filing

- Unscrewing

- Deburring

- Masking

- Impact unscrewing

- Clipping

- Door trim assembly

Vibration qualification tests were carried out by CETIM. These tests have shown encouraging results regarding the possibility of using the glove as a standardised vibration sensor.

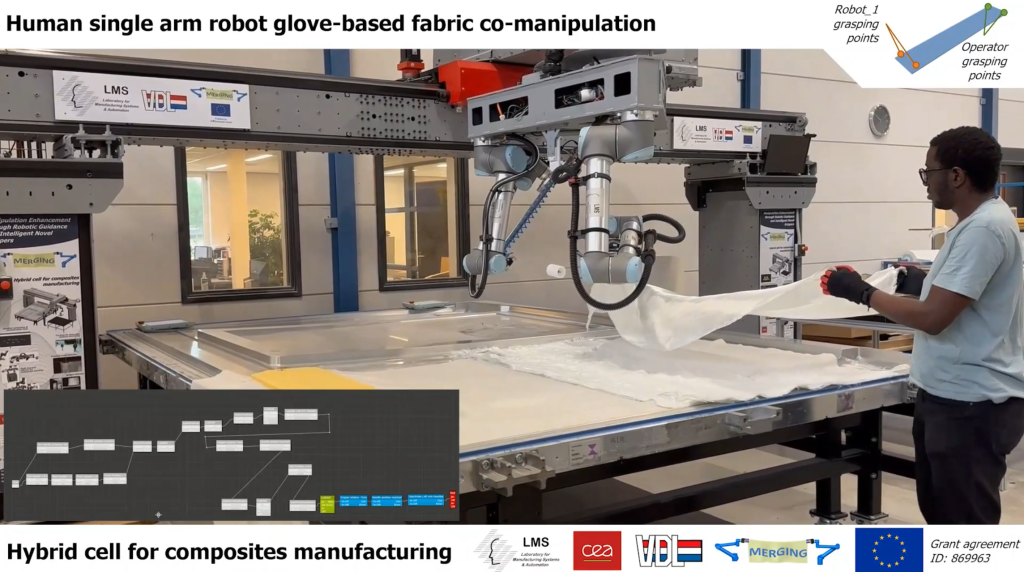

The gloves have also been used in the European Merging project (grant agreement ID: 8869963) as a tool during robotic co-manipulation to move soft products (such as textiles).

The gloves have also been used internally as a robotic interaction tool.

The glove makes it possible to co-manipulate an industrial robotic arm. The synchronous acquisition of the effort signal oriented in space from the gloves makes it possible to steer an industrial arm.

Outlook

The glove is being engineered for production by our partner RACER and marketing is scheduled for late 2025.

Contact: Patrick Freu, Product Development Manager, pfreu@racerfrance.com

European and internal research projects continue on the subject of co-manipulation of robots with the gloves developed during the project.

Conclusion

In the course of the project, we had the opportunity to develop a complex embedded system for use in industry.

Today, the technology is being transferred to a partner.

The glove, initially designed for ergonomics, has found many other internal and external use cases, in a number of areas.

Author: Adrien CHAMBELLAN, ERGOHAND Project Manager, CEA-List.