Project conducted by the FactoryLab, industrial consortium, led by CETIM in collaboration with Nimesis, Naval Group, Stellantis and Safran.

The key concern of sealing

Today, sealing is an essential component in the life of fluid systems and processes in order to guarantee optimum performance, make people and property safe and also protect the environment. Besides, shape memory alloys (SMAs) have revolutionised materials engineering thanks to their remarkable ability to go back to their initial shape after they have undergone deformation. That unique characteristic is the result of reversible changes in the crystalline structure of SMAs, which are triggered by constraint or temperature variations. When these alloys are heated beyond their transition temperature, they change from a deformed martensitic phase to an undeformed austenitic phase, which allows them to go back to their pre-established shape. That intrinsic capacity offers huge innovation potential in a number of industrial areas, particularly sealing.

SMAs, a trump for controlling clamping and sealing?

Current challenges in the areas of clamping and sealing in a number of industrial sectors bring out the need for innovations in those fields. Conventional methods, however widely used, have significant limits, particularly as regards thermal variations and mechanical constraints. Those limits result in high maintenance costs and unscheduled downtime, thus making the need for more reliable and effective solutions more acute. Research into SMAs aims to address those challenges by finding ground-breaking and adaptable solutions.

The key innovation of our feasibility study lies in the design of clamping and sealing devices incorporating these new SMAs. These devices exploit the properties of SMAs, in order to allow constant and reproducible clamping and reliable sealing, including in extreme environments.

A well known mechanism

SMAs take advantage of phase transitions to go back to their original shapes. At ambient temperature, they are in a deformed martensitic phase. However, when they are raised to a temperature above their transition temperature, they change to an austenitic phase, thus going back to their pre-set shape. This process is reversible and can be used in a controlled manner to produce a movement or a required deformation.

Usefulness to be demonstrated in clamping and sealing applications

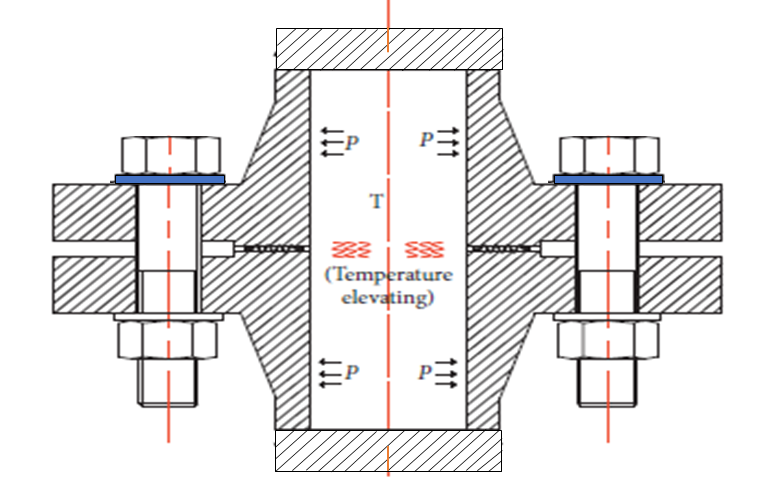

The application of SMAs in the field of clamping and sealing relies on their adaptability to environmental variations. Clamping systems that use SMAs can be designed to contract or dilate in response to temperature changes, thus ensuring constant clamping in dynamic thermal environments. Similarly, seals can be optimised to maintain constant pressure in spite of temperature and pressure fluctuations.

That adaptability of SMAs to environmental conditions offers significant benefits in applications such as industrial assembly, where temperature variations are common, and in environments subjected to variable mechanical constraints. These properties make SMAs promising candidates for rising to the complex challenges of clamping and sealing in a wide range of industries.

Results to be developed further

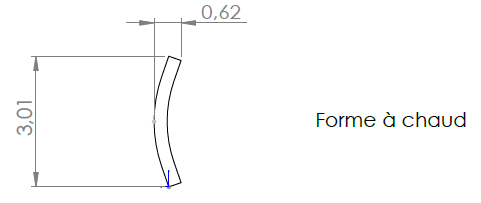

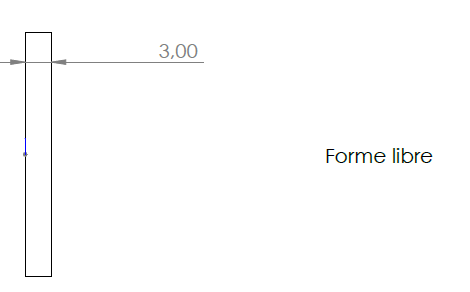

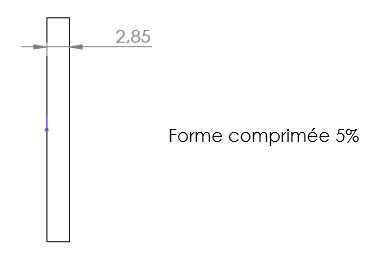

With our partner Nimesis, we have designed two prototypes to assess the performance of these materials in sealing systems:

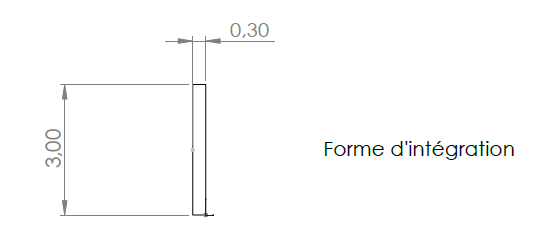

- A washer to replace washers with nuts that must make it possible to maintain the pressure applied on the seal;

- A tape housed in the groove of an O-ring seal and which, as it is deformed, applies additional force on the installed O-ring seal.

Based on the input data supplied by CETIM, Nimesis has designed, sized and manufactured the two prototypes. As part of this feasibility study, we have opted for material that is entirely made in France in order to control the entire supply chain.

The results of the study do not show substantial gains in sealing performance. Several factors may be behind these test results (deformation, thermal dilatation, surface condition etc.), meaning that they do not demonstrate that these materials are ineffective. Indeed, another test has enabled us to show the working of the washer, so we know that the design is capable of working. On the other hand, it is clear that its implementation does not obviously improve the sealing of the system. However, the arrangement does seem promising and probably opens new perspectives in the area of industrial clamping and sealing. All the same, several limits must be considered:

- A more complex design of the sealing connection;

- Applications with greater temperature restrictions. We have not been able to consider the conditions of the applications of our industrial partners for that reason;

- High cost;

- Sovereignty of the supply. Some materials are not sufficiently, or even not at all produced in France.

Prohibitive cost?

While the immediate sealing performance (i.e. no measured gain but also no deterioration) is not as expected, it needs to be assessed over the long term, to see if the compensating effect of SMAs is more marked.

Besides, more in-depth research into the test assemblies would be necessary to optimise their design.

Lastly, after demonstrating possible gains, a study would be needed in respect of the cost of such materials.

Conclusion

To conclude, this study of the use of shape memory alloys for clamping and sealing did not represent a significant advance in the area of the design of sealed connections. Nevertheless, our innovations do open new perspectives for the improvement of performance over the long term. As of now, however, such systems do not appear competitive enough for large-scale engineering, in view of their performance and the complexity of their design.

Author: Pierre-Henri DUBOIS, CESAME F Project Manager, CETIM.