Project conducted by the FactoryLab industrial consortium with cross expertise from CEA-List and CETIM, in collaboration with Safran, Naval Group, Stellantis and SLB.

Background

Artificial intelligence (AI) is developing very rapidly and offers numerous opportunities to redesign certain tasks in order to enhance productivity, cost effectiveness and reliability. The area of non-destructive testing, particularly X-ray examination, is no exception.

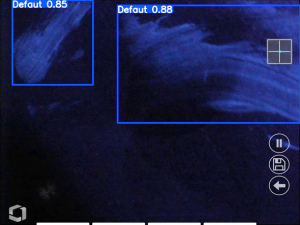

In particular, the analysis of X-ray images represents high potential for AI, and applications are already in place in some companies. These applications often take the form of algorithms that help decision making, highlight indications to the inspector, and in some cases make automatic decisions if they have been qualified for the application of acceptance criteria in addition to the detection of indications.

The major difficulty while putting in place a system to assist in decision making or for automatic decision by AI is that a sufficient quantity of data are required. Indeed, training a supervised detection algorithm (“standard” algorithm) requires several hundreds of images as a minimum, including an adequate diversity of each of the types of indication to be found.

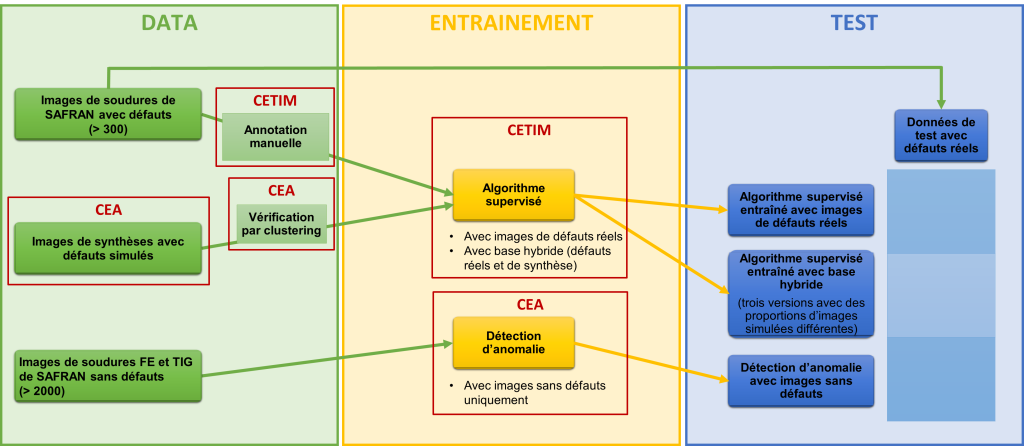

Consequently, the aim of this project was to study the possible solutions that allow the implementation of an algorithm for detecting indications on X-ray images when few images are available to train a standard algorithm. To that end, five algorithms were trained, making it possible to compare three different approaches:

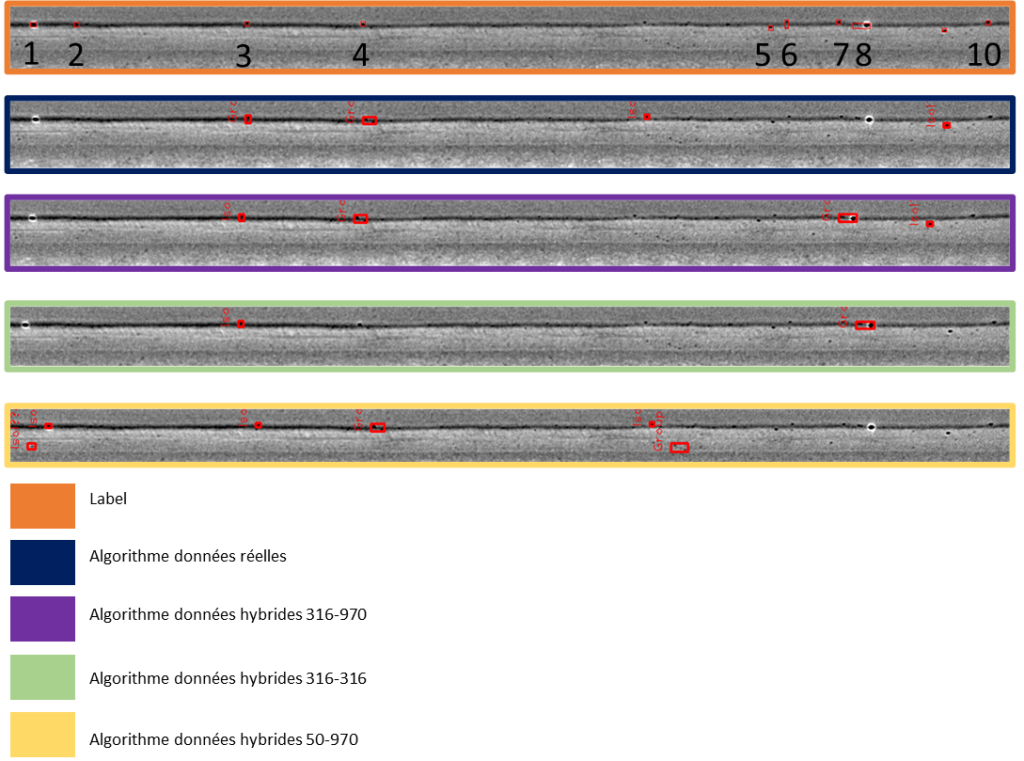

- A supervised algorithm trained on an image base with actual defects that have been manually annotated: this algorithm, which is the standard solution that is often found deployed today, is intended to serve as the measurement standard for the other tested approaches.

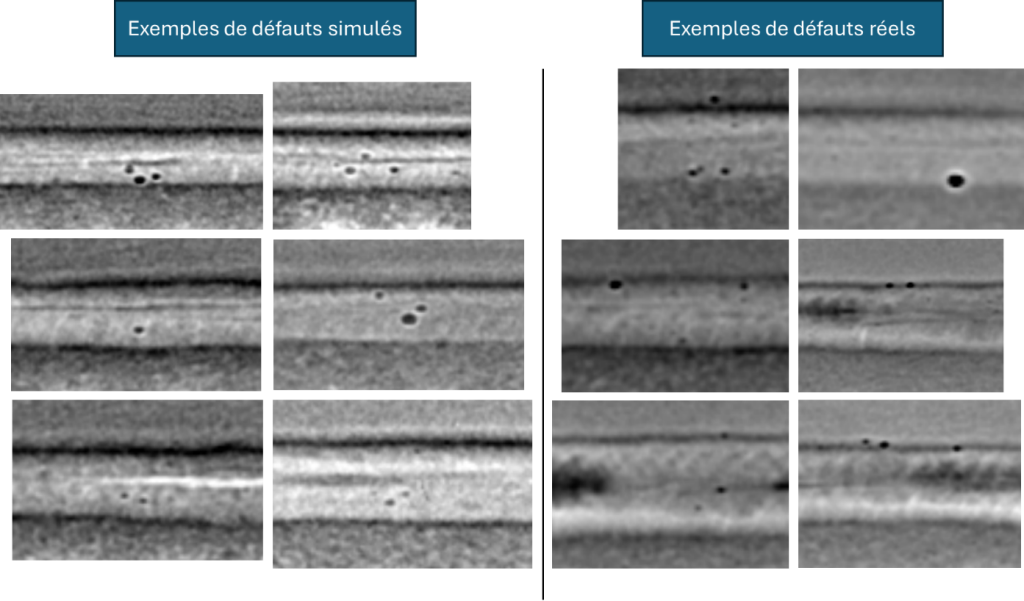

- A supervised algorithm trained on a hybrid image base, made up of both images with actual manually annotated defects and actual images on which artificial defects were added by simulation. This method offers a way to make up for the shortage of images with defects. Three versions were tested as part of the project, with the same algorithm trained on different proportions of images with actual defects and images with simulated defects.

- An anomaly detection algorithm (known as a “one-class algorithm): these algorithms are trained only using acceptable images, which means that they can even be put in place in applications for which there are very few images of defects.

Use cases and project stages

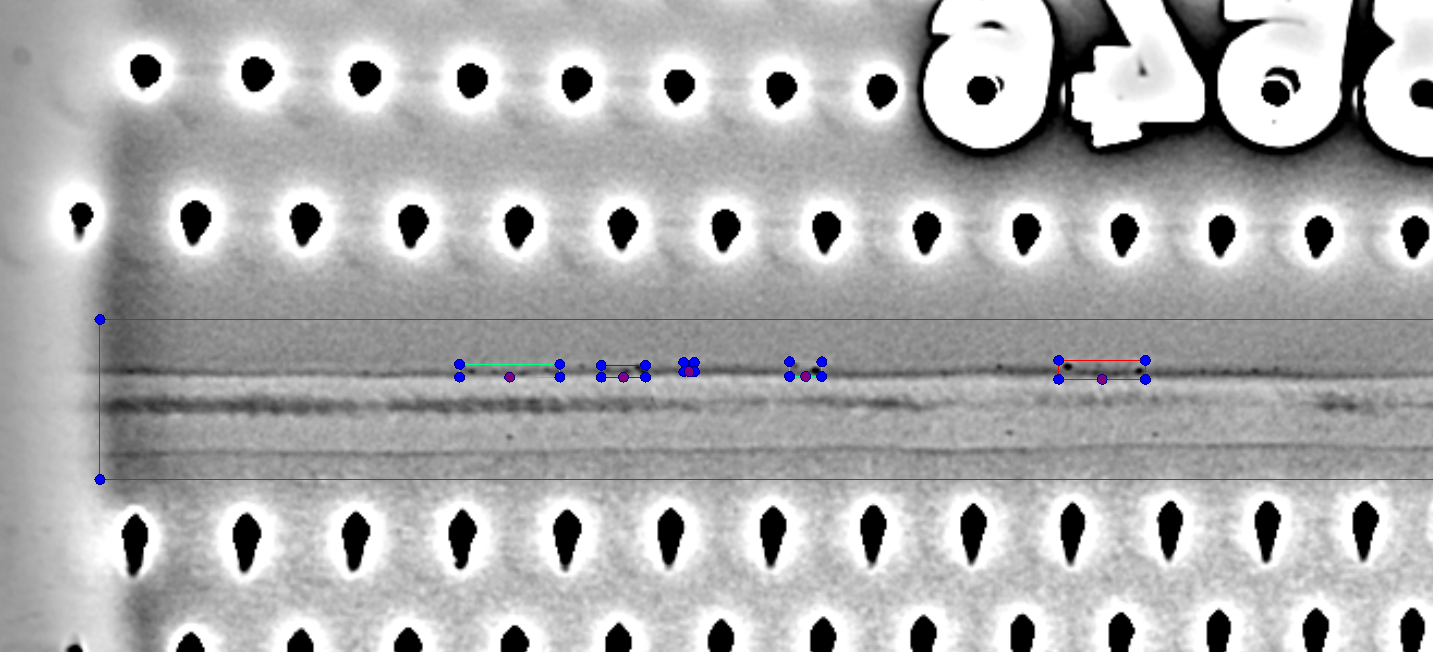

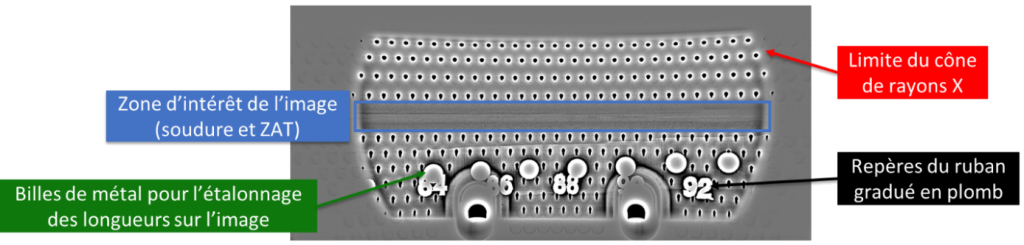

The study was conducted on digital images of electron beam welds of combustion chambers supplied by Safran. Three types of indication were searched: isolated porosities, grouped porosities and inclusions of tungsten in TIG welded areas. However the results were very limited as regards tungsten inclusion detection because of the lack of images present in the database. In all, 400 images with indications and several thousands of defect-free images were supplied for the project.

Manual annotation was provided for all the images with indications to allow the training of the reference standard algorithm.

Defect-free images were used directly to train the anomaly detection algorithm, with an extensive test phase to determine which algorithm was to be selected from all those available to date.

A thousand computer generated images were generated by simulating the absorption of X-rays of porosities and tungsten inclusions using software in a model of the part, and by including these defects in actual images without indications. The same supervised algorithm was trained, in addition to the set of images with actual defects, on three sets with different proportions of actual images and computer generated images.

Results

Comparative tests were carried out between the different algorithms trained on a database of actual defects containing 185 annotated indications. The algorithms all provided promising detection results, with 62% significant indications detected by least effective algorithm, and up to 87% by the highest performer. These results are inadequate for the complete replacement of human inspections in critical applications, but can be sufficient for implementing a system to assist decision making.

In spite of the higher number of false positive results, the anomaly detection algorithm (trained only with images without indications) provided the best results, particularly with a clear advantage when it came to detecting isolated porosities. Note that this type of algorithm does not allow the classification of indications by type, unlike the other tested algorithms.

The four supervised algorithms, three of which were trained on hybrid bases including computer generated images, provided results that were very similar overall, in spite of the marked differences while observing the annotations image by image.

Conclusions and outlook

The study brought out the relevance of the two approaches studied for putting in place AI systems in cases where the initial data are insufficient for training a standard supervision algorithm, with performance that was equivalent or even superior, compared to a standard supervised algorithm, for the case study selected.

The results obtained in the study can be perfected by testing different use cases. The reliability of the results could also be confirmed by following several suggestions detailed in the study report (modifying image display management, duplicating training to check the convergence of results etc.).

Author: Nicolas DANKAR, AUTO RX Project Manager, CETIM.