Project carried out as part of the industrial consortium FactoryLab, conducted by CETIM in collaboration with Stellantis and SLB.

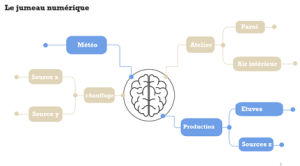

Drawing on the success of the FactoryLab SmartStandBy project (2023-2024), which was aimed at identifying potential electricity savings in manufacturing plants, the Smart Water project (2024-2025) applied a similar approach to industrial water.

The goals of the SmartWater project were to:

- Instrument and collect water data from two manufacturing sites for the different uses (manufacturing and offices), the distribution system and the associated discharge;

- Develop a methodology and protocols for adjusting water consumption (water conservation plan), particularly for maintenance and production managers, regarding the working of production equipment and utilities;

- Test the methodology for two manufacturing sites (instrumentation and tracking of water data + recommendations for optimisation + assessment of gains);

- Issue and capitalise on recommendations to reduce water consumption using the improved technology available, good practices by type of production equipment, monitoring of the system/leaks, water recovery/reuse/treatment etc.

Challenges

The challenge of the SmartWater project was to initiate work on the water cycle in two large manufacturing sites:

- A regulatory analysis and summary of the two catchment basins in question (Sochaux and Béziers);

- Stellantis Sochaux with a focus on the audit of the pressurised water system, consumption metering and leak detection;

- SLB Béziers with a focus on optimising water treatment processes to identify possible reuse and recycling, and a critical analysis of the treatment performance of three audited pieces of equipment.

The common requirement of the two end users was to improve control over the water cycle through better metering, reduced consumption and treating for processes exactly to needs.

Background

Stellantis use case:

The SmartWater use case was the whole industrial water supply system which provides water to all the industrial units in the Sochaux facility. The scope was limited to the supply part, without going into the production buildings, as these were undergoing major reorganisation and redesigning work at the time of the project.

SLB use case:

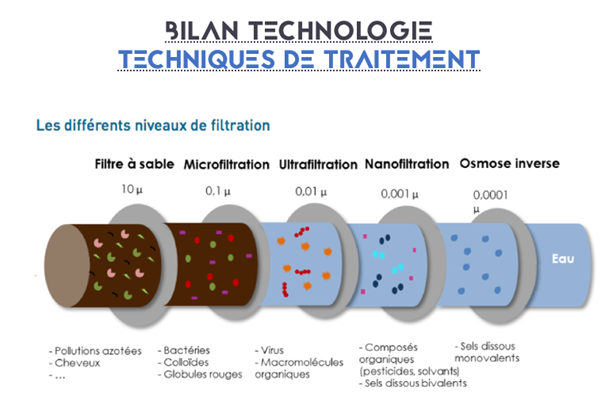

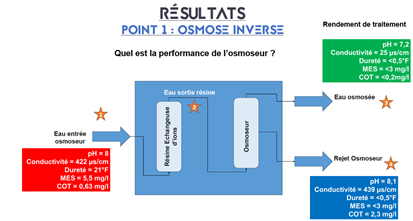

As a perfect complement to the Stellantis case, the SLB use case related to the interior industrial unit, with a focus on several water treatment processes (reverse osmosis unit, activated carbon filters, resin filters etc.) to assess their respective performance and the potential cascaded reuses possible.

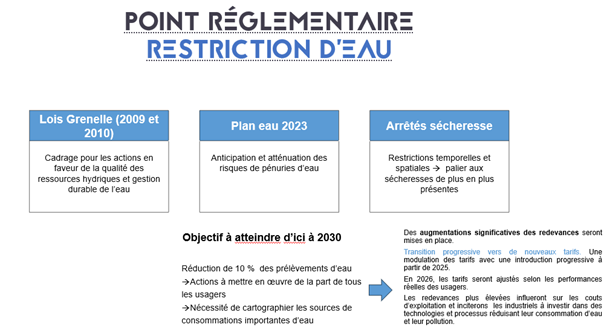

Regulatory analysis and summary

At the start of the project, research and summaries were carried out to provide the regulatory framework and the associated tools, particularly compliance with the water conservation plan that water-consuming companies are required to provide to the regulatory authorities.

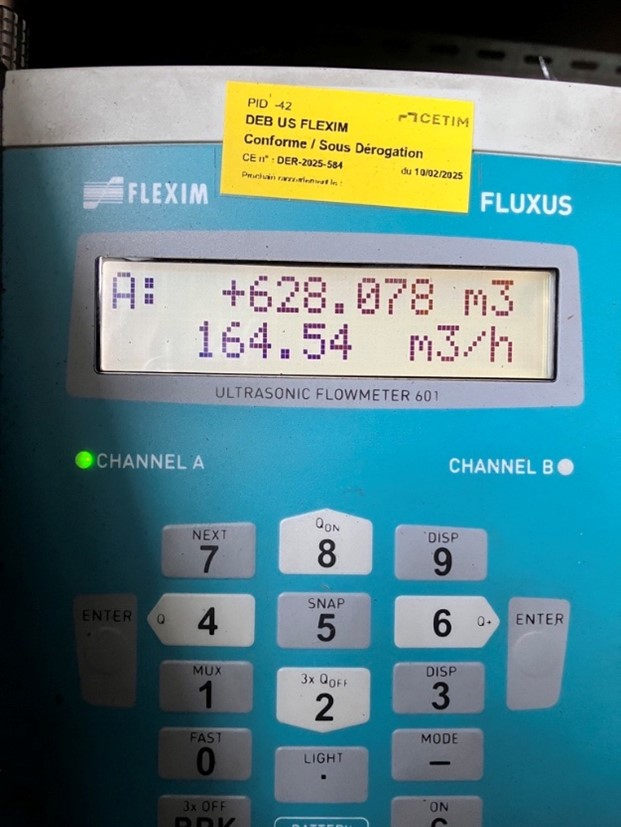

Flow measurements and leak measurement campaigns

The aim of this part was two-fold: measuring certain unknown flows to improve the mapping of the industrial water system of the site and conducting a leak detection campaign on part of the industrial water supply system.

The two main technologies used were non-intrusive flow meters (ultrasound technology) and a pilot system for leak detection through micro-ultrasound applied on the pipes and used in combination with an AI signal analysis algorithm (similar to the French navy’s “golden ears”).

Analysis of water treatment system performance

This part was aimed at measuring the characteristics of the industrial water before and after treatment equipment in order to assess the effectiveness of the equipment. By combining that with flow measurement, it became possible to assess the performance of reverse osmosis, activated carbon filtering and resin filtering. Those assessments allowed the suggestion of possible optimisation measures and recycling: indeed, the water from a first operation showed characteristics and quality that were adequate for use in a second operation, before it was sent to treatment and discharge.

These analyses make up the fundamental part of the REUT initiative relating to the reuse of treated industrial water and make it possible to significantly increase the recycling rate of industrial water.

Impacts

The SmartWater project has had several positive impacts:

- The discovery of the concept of water footprint applied to a manufacturing site;

- Improved awareness of water issues in industrial processes;

- Improved knowledge of the strong points and weaknesses of the industrial water cycle, in terms of efficiency (absence of leaks) and also performance (process water treatment);

- The fact that water is no longer considered to be solely as a utility with a low financial cost, but also as a resource that is growing rarer and which could in future restrict the activity of a site in the event of drought measures;

- Improved knowledge of the water conservation plans required by the DREAL (environmental authority).

Conclusion and prospects

The SmartWater project took place from September 2024 to September 2025 and allowed the participating companies (Stellantis Sochaux facility and Béziers facility of SLB) to be supported by CETIM in this FactoryLab project.

Leak detection on the pressurised water system with ultrasound combined with AI analysis, assessment of the suitability of water treatment for needs, water footprint approach, and assistance for water conservation plans were some of the areas in which personalised diagnoses and recommendations were made. The SmartWater project made a valuable contribution to the national REUT initiative for the reuse of treated waste water by industry.

Référents industriels :

Stellantis: Patrice Huck and Christophe Léchine

SLB : Charles Mourgues

Project Manager, CETIM:

Nicolas Cortesi, SmartWater Project Manager

Miguel Cruz, contact for Water in the Energy and Environmental Transition activity

Godelieve Laffranchy, engineer responsible for regulatory industrial water analyses and summaries

Thomas Lapoire, engineer responsible for measurement and instrumentation

Photo credits: CETIM

Author: Nicolas CORTESI, CETIM.