Project carried out as part of the industrial consortium FactoryLab with CETIM, CEA List, SLB, Safran, Stellantis and NAVAL GROUP.

Background

Control of ambient temperatures in production workshops does not include placing instrumentation close to workers or take account of the energy gain from manufacturing processes. In the absence of such a system, ambient conditions end up being degraded, with over consumption of energy and decreased productivity.

The aim of the COGEFLUX project conducted by the FactoryLab industrial consortium was to control energy consumption in manufacturing workshops, at the same time making sure workers enjoy optimum working conditions.

Challenges & innovation

The purpose of temperature control in buildings is to keep users comfortable, which is a subjective feeling. One individual may be very happy to work in a workshop at 17°C, while another may not be comfortable in a room at 21°C.

The aim of the COGEFLUX project was thus to provide tools to better manage temperature in areas through the following:

- Assessing the existing system using a generic method

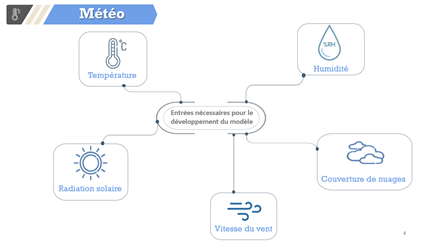

- Adding instrumentation in workshops and thermal machinery based on optimised comfort criteria

- Promoting readiness and upskilling in the IoT and digital twins (architecture, data management) via CEA List

- Tools for controlling, steering and predicting energy consumption for heating

- Choice of KPIs for the control system in terms of cost, deviation from setpoints and temperature gradients

- KPIs for ergonomic interfaces, in relation with the already existing system.

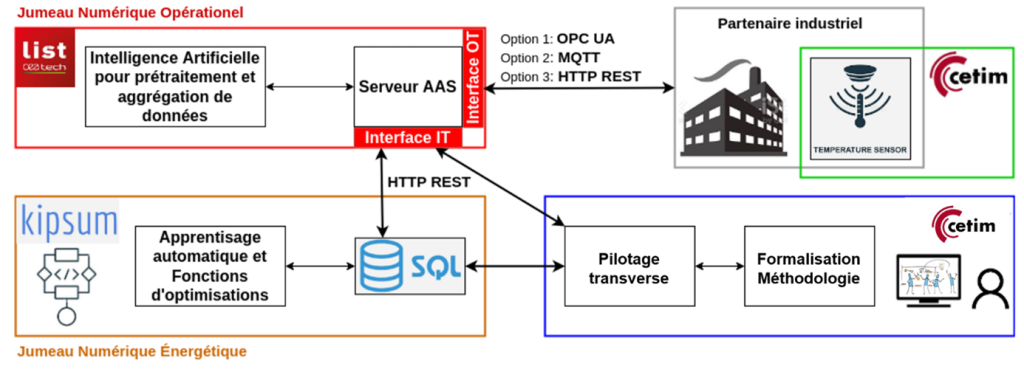

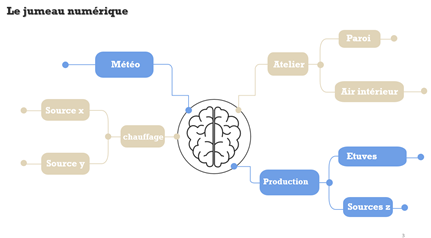

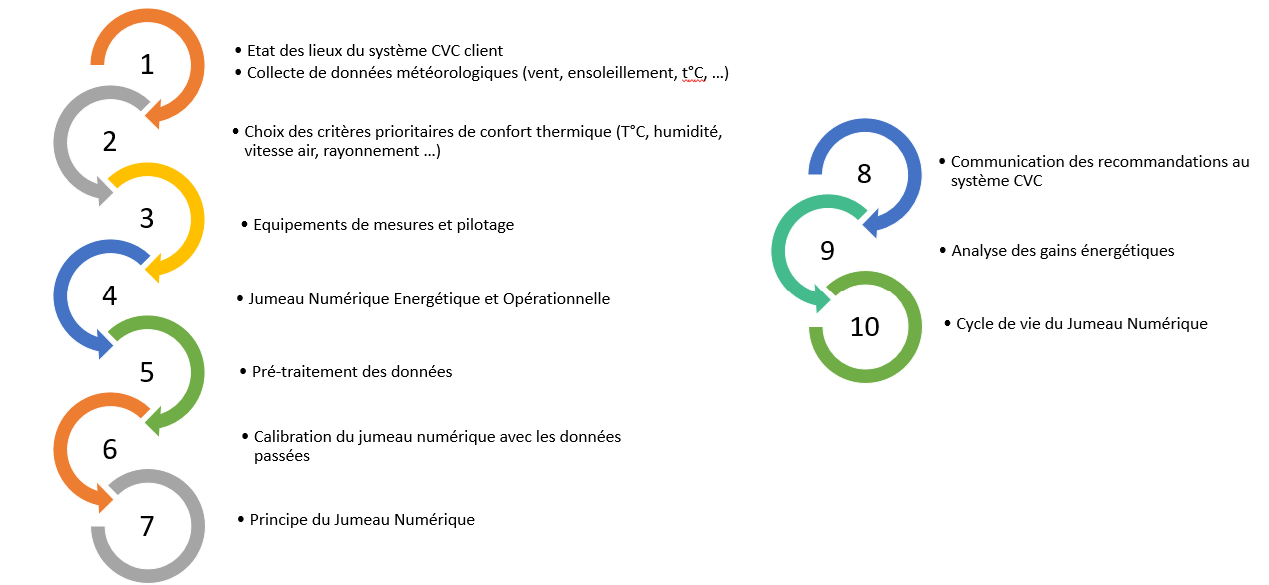

The main innovation in this project thus lies in the use of the synergies between technological means (instrumentation), methodological approaches (digital twin construction process) and machine learning tools (data acquisition, digital twin and continual optimisation) in order to reduce the energy consumption of workshops by means of an optimised multi-criterion control system.

Results

The study covered three use cases:

- Collection, analysis and pre-processing of energy data from a production workshop of Stellantis. Modelling of the energy consumption of the workshop using a digital twin. Identification and implementation of measures to optimise thermal comfort by lowering the heating setting so as to save energy, about 10%.

- Modelling of the energy consumption of a production workshop of Safran via a digital twin. Identification of the most effective and relevant future measures to optimise thermal comfort by heating exactly to needs.

- Collection and analysis of energy consumption data from the 60 metering points of the site of SLB over the last 6 years. Creation of a secure data server for the organisation and standardised exchange of energy values, with a digital twin.

Cogeflux thus made it possible to develop a methodology for optimising thermal comfort based on:

- A method for taking back control over the heating system

- An energy digital twin

- A noise-reduction and data correction tool

- A standardised tool for the secure exchange of energy data

The data already collected by the BAS can be analysed in greater depth to populate mathematical heat behaviour models. The mathematical model can then be used to offer a way to optimise the energy consumption of buildings. Such use may be made as and when necessary or dynamically via a digital twin.

In this project, regarding data processing, we addressed pure analysis subjects (choice of programs for formatting, choice of types of logic for identifying errors, choice of equations for correcting errors) and also technical IT issues relating to data transfer (servers, docking, formatting) for digital twin operation.

Conclusion and prospects

The COGEFLUX project has demonstrated its value to different end users. However, in view of the operational difficulties encountered during the project (knowledge of boiler controllers, difficulty of bringing in outside parties, data collection, internal investment times etc.), the delayed application of recommendations made it impossible to assess the energy saved over a sufficiently representative heating period.

This project also helped the partners achieve more readiness in this area of work, by helping them take back control over their heating system and gain a better understanding of the factors that influence the regulation of thermal comfort. The use cases did not make it possible to deploy all the components identified in the project in terms of control and prediction, but results show valuable potential energy savings (of about 10%).

The feedback capitalised as part of the methodology was shared with end users in order to enable them to deploy the recommended measures by the next heating season in their various production workshops.

Author: Jérôme RIBEYRON, COGEFLUX Project Manager, CETIM.