Project conducted by the FactoryLab industrial consortium with the expertise of CEA-List, CETIM and IQANTO (PREDICT), in collaboration with manufacturers Safran, Naval Group, Stellantis and SLB.

Background

Welding equipment and new generations of sensors allow the singular and comprehensive reporting of data about the physical aspects of the process. But these data are currently very poorly exploited, if at all.

Challenge & innovation

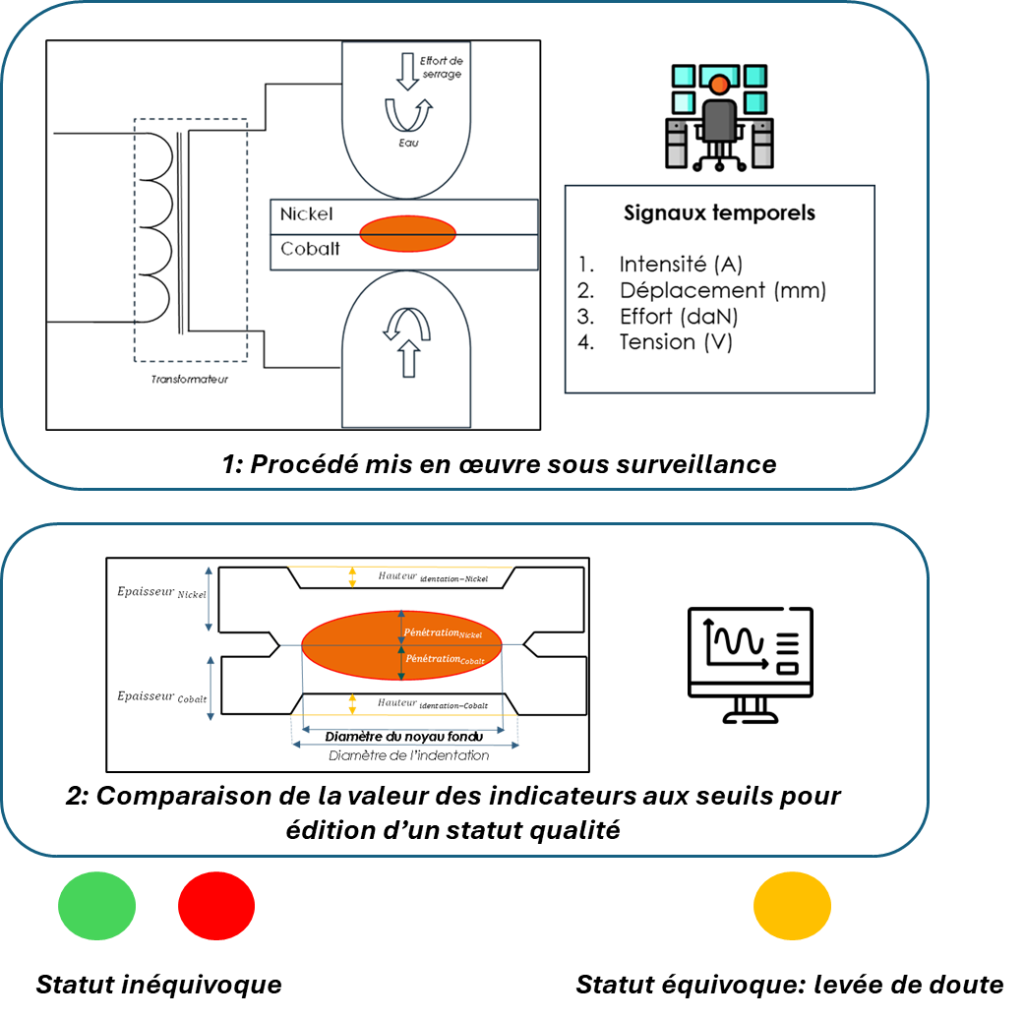

The challenge of the RACOSOUD project was to identify, based on the processing of these data, the indicators that unequivocally indicate a welding defect or to issue a report in order to schedule a special inspection at a later time.

The industrial challenge relating to the resistance spot welding process is significant because quality monitoring using conventional approaches (e.g. non-destructive testing) remains difficult for such joints. In that regard, the project also included a part relating to the development of effective multi-element ultrasonic non-destructive testing to complement the work on data use.

For the RACOSOUD project, IQANTO used its KASEM® digital solution coupled with IA technology for three monitoring strategies to establish causal/correlation relationships between process data (intensity, voltage, force, displacement etc.) and the quality of the weld made.

Strategy 1: Establishment of the link between the time signals and the quality of the welded spot.

Strategy 2: AI approach to establish the link between the indicators calculated by Strategy 1 and the quality of the welded spot.

Strategy 3: Establishment of the link between the set point and the quality of the welded spot.

Results

As part of the project, a resistance welding machine used by SAFRAN Helicopter Engines was instrumented with sensors for recording physical data felt to be relevant in order to characterise the quality of the joints made.

An experimental design made it possible to establish correlations between physical values and the quality of joints.

The project and the results obtained stand apart from the scientific literature about predicting the quality of a joint by analysing welding records in the following aspects:

- The experimental design included the impact of all the influencing factors on the quality obtained while welding, particularly by incorporating the conditions of wear and tear of some components, the surface condition of the welded plates etc., while the cases studied in most publications only cover the impact of process set points (variations of operating set points on the welding power source);

- The study was applied to materials known as aviation materials (nickel and cobalt based), whereas studies usually relate to unalloyed steels;

- The data processing approach included three stages:

- A first “human” analysis of the data in order to establish simple correlations between the data logged and the quality of welded spots;

- A second “automated” routine using tools derived from artificial intelligence technology, establishing more complex correlations between data and quality;

- A critical comparison of the two processing results obtained and the final establishment of indicators to monitor the quality of welded spots.

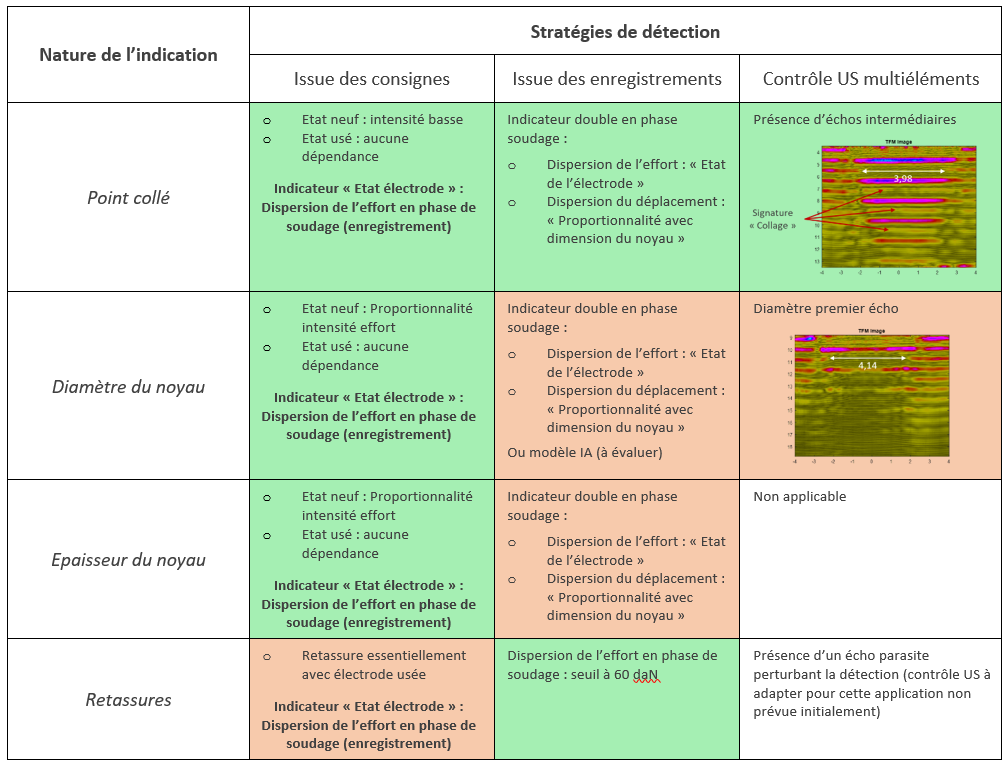

Below is a summary table of the different strategies that can be used to monitor the quality of resistance spot welds. The colour code indicates the level of robustness of the indicator obtained to date.

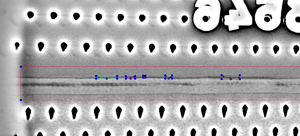

The project also made it possible to continue the development of an effective non-destructive testing solution for resistance spot welds (multi-element US), which complements the prediction of the quality of joints by monitoring process data. Multi-element US testing is aimed at finally determining the quality of a resistance spot weld when doubt has been raised by the monitoring of parameters. The test made it possible to bring out the effective detection of “stuck” welds. In respect of the assessment of the diameter of the welded spots, the study shows promising results, which are however not entirely satisfactory because of the surface condition of degraded weld spots, which are not necessarily representative. Lastly, in the case of shrinkage cavities, the sensor used was not suitable, because this point was not covered by the study defined initially.

Among the results obtained with the technology used by IQANTO, the following are of note:

- The detection of a change in behaviour of the intensity with the confirmation that the deviations observed are due to a sensor calibration problem;

- The detection of a slow upward drift of the dispersion of the displacement of the welding electrode, making it possible to envisage the monitoring of the wear and tear of electrodes.

Conclusions

The project made it possible to use a number of physical values (force, displacement, current and voltage) in different forms (median, dispersion, integral etc.) in order to identify the complex correlation links with the quality of resistance spot welds.

That work has resulted in the establishment of different indicators to monitor the quality of the weld, which remain to be tested in a production environment away from the experimental design.

Outlook

What is needed now is to continue the assessment of the relevance of the established indicators in a production environment (away from the experimental design) in order to engineer the solution for production.

That is the goal of the continuation of the collaboration between SAFRAN Helicopter Engines and IQANTO, as they look to make the monitoring indicators developed during this early phase more robust. To that end, production data from several dozens of batches of welded parts will be collected, processed and analysed in order to improve the early detection of welding abnormalities and envisage indicators that can predict the nonconformity of the welded spots.

Authors: Samuel CRETIN (CETIM), Hugues LOURME (CEA-List), Florent BARBIER (IQANTO)..